Welcome to 2023, everyone! We’ve got a lot of great things on the roadmap for 2023 and we’re starting it off with the new Demand Estimator. For the next 6 months, unlimited use of the demand estimator is available to all organizations at all service levels. After 2023-06-30, usage limits will apply.

Supply Chain Nightmares

The past two years have been very challenging for manufacturing organizations. With lead times stretching out to previously unimaginable timelines, there has never been a greater need for tools that help companies understand the demand for their product well into the future.

Last year, we introduced the Safety Stock Manager and Material Shortage Report, two tools deployed to help you manage long lead times and the increasing need to drive your production planning further into the future. We also introduced the Inventory Forecast Chart to provide real-time visualization of any component’s inventory trajectory.

As these tools pushed the planning boundary further into the future, our most savvy customers recognized that they needed to also have a solid understanding of understand customer demand up to, and beyond, this boundary.

What is Demand Estimation?

We wanted to provide you with a sophisticated tool to represent your customer and channel demand in a manner which integrates well with Aligni’s existing capabilities and world-class build management. We also wanted to provide sophisticated component-level reporting for our PLM customers that aren’t using the MRP functionality because we know that savvy organizations can use this to engage suppliers with more comprehensive information about where they’re headed.

Product Demand Entry

The first step is demand entry. Who needs what, when, and how many? These are simple questions with an often complex answer but when this information is captured natively in Aligni, it offers gateway to a ton of new capability.

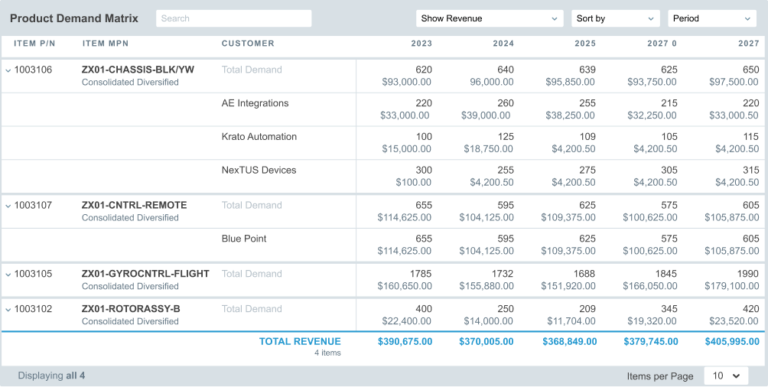

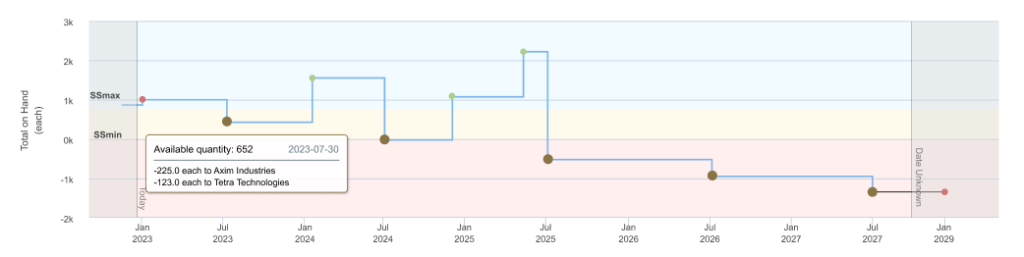

With each demand entry, we capture the product, the customer (or channel), the quantity, the revenue-per-unit, and the date of demand. When loaded into Aligni, you’ve got a beautiful matrix of production and financial forecast.

Demand and Production Planning

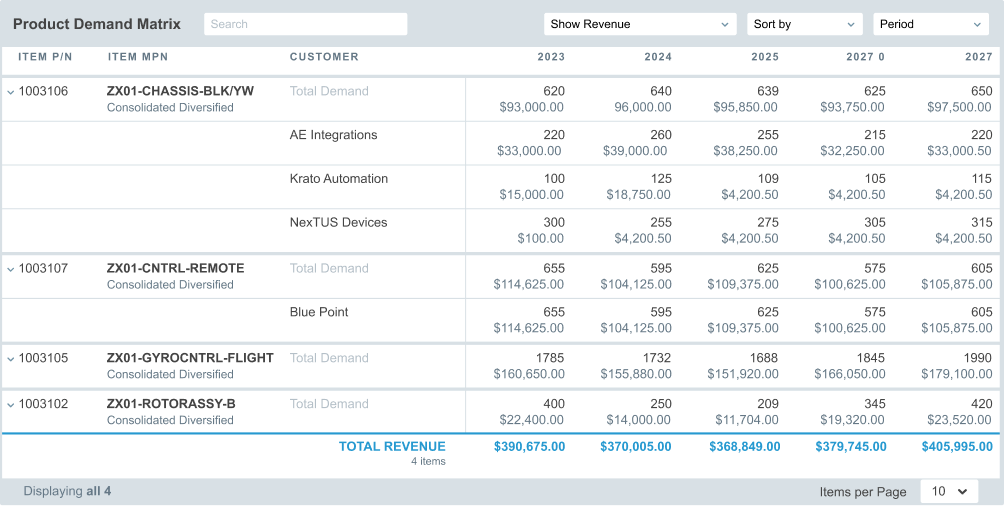

Before the demand estimator came along, your production schedule (allocated builds) only created assembly products — there was nothing to balance that production with consumption. Demand entries now provide consumption (decreasing inventory) of finished goods so you can easily see the balance of production and demand.

This new balance allows your production team to target safety stock ranges for finished goods as well as components. Safety Stock TimeWarps and the inventory forecast chart are also demand-aware, so your team can peer into the future with confidence.

Component Demand

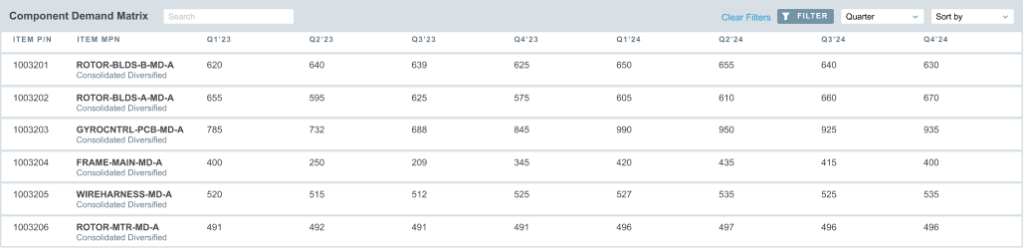

The most exciting part for our PLM customers is the component demand information. With product forecasts entered, Aligni can now composite all of the material requirements and provide an accurate forecast of your future component needs.

If you’re on a PLM product (i.e. not using Aligni MRP), you may not be using Aligni for production planning but you can still share your forecasts with component suppliers and manufacturing partners. This information helps them plan and execute more efficiently. It can also help you negotiate relationships with more accurate and comprehensive information.

What the Future Holds

We’ve got a lot in store for this new world of demand estimation. Stay tuned!

For more information, make sure to visit our Demand Estimator documentation.

Start your 30-day free trial

Helping You Make Great Things…Better.