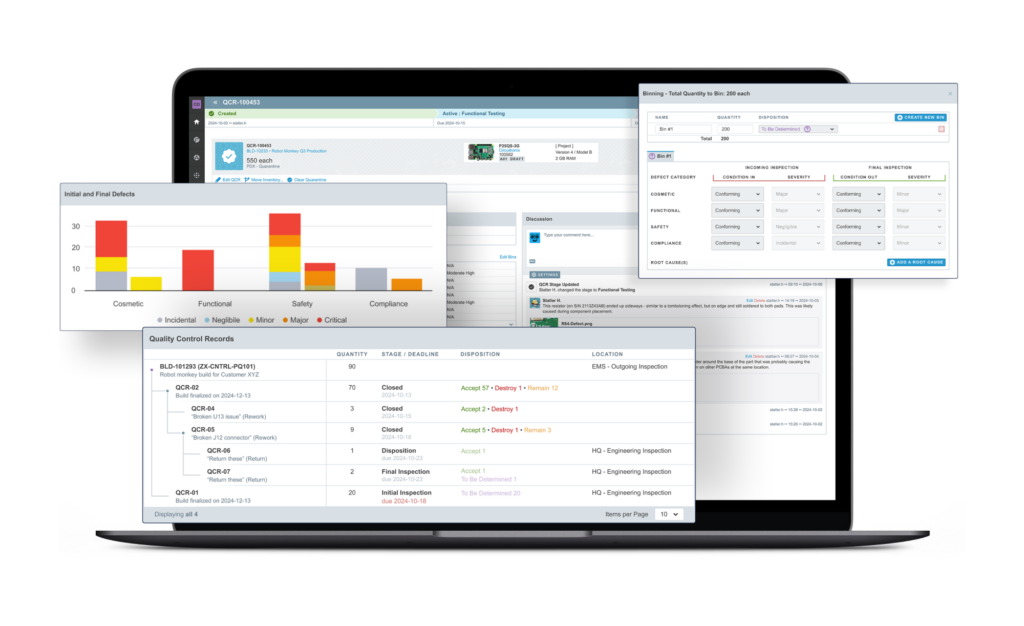

Improving Manufacturing Collaboration with Aligni DiscussAnything

In the fast-moving world of electronics manufacturing, keeping production efficient isn’t just about machines and materials—it’s also about how effectively people communicate. Traditional methods like email threads, meetings, and scattered notes often slow things down, especially…