MRP

Enhancing Collaboration with Aligni MRP

To be efficient at manufacturing, a company has to rely on several groups within its operations and each is highly specialized at what they do. All of these groups need to work together to make manufacturing as efficient as possible.

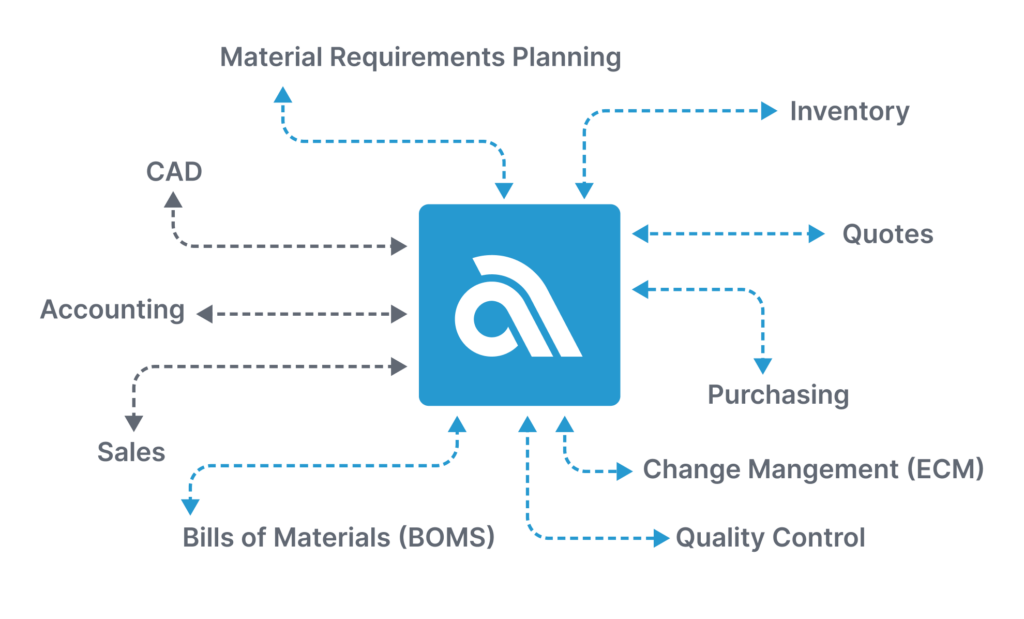

When these groups have their own processes to manage that interconnection but only slightly overlap, it’s difficult to make sure everyone is on the same page. That’s why it’s important to use a business system that connects purchasing, production, quality, inventory, and other groups together in a way that makes sense while making things more efficient. For small and medium sized manufacturing firms, that system is a Material Requirements Planning (MRP) system.

Systems like Aligni MRP act as a company’s information hub. They are designed to provide access points that not only connect these functional groups but provide interfaces that align with the processes each group uses. This produces the collaborative effects that make so many firms successful.

Below, we’ve outlined some of the biggest ways where Aligni MRP can increase a firm’s productivity and reduce issues through building operational consensus.

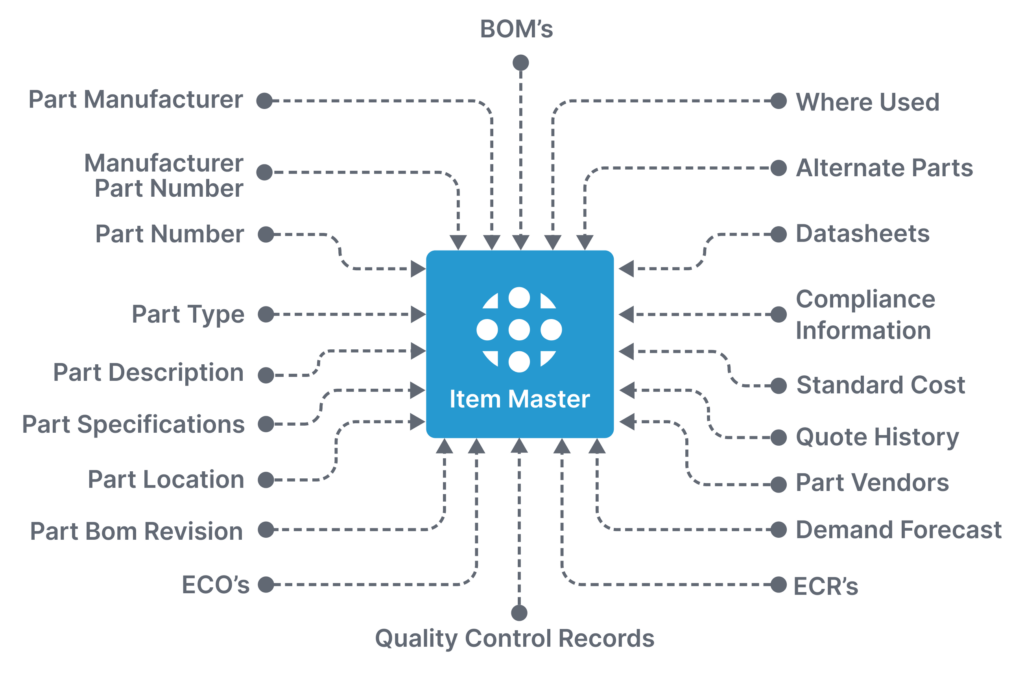

Centralizing Data

Aligni materials requirements planning software provides the foundation to eliminate data silos and reduces the risk of errors caused by outdated or conflicting data stored locally or across the organization. Aligni MRP’s item master database serves as a central repository for all product-related data, including design files, specifications, BOMs, vendor availability, pricing, quality aspects, and change orders history. Managing all this data within one application ensures all departments have access to the most up-to-date and accurate information when they need it.

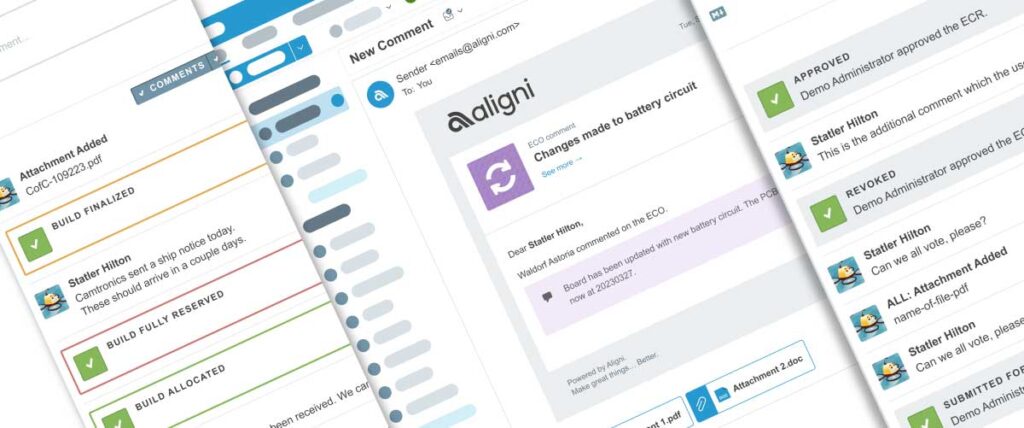

Collaborating in Real-Time

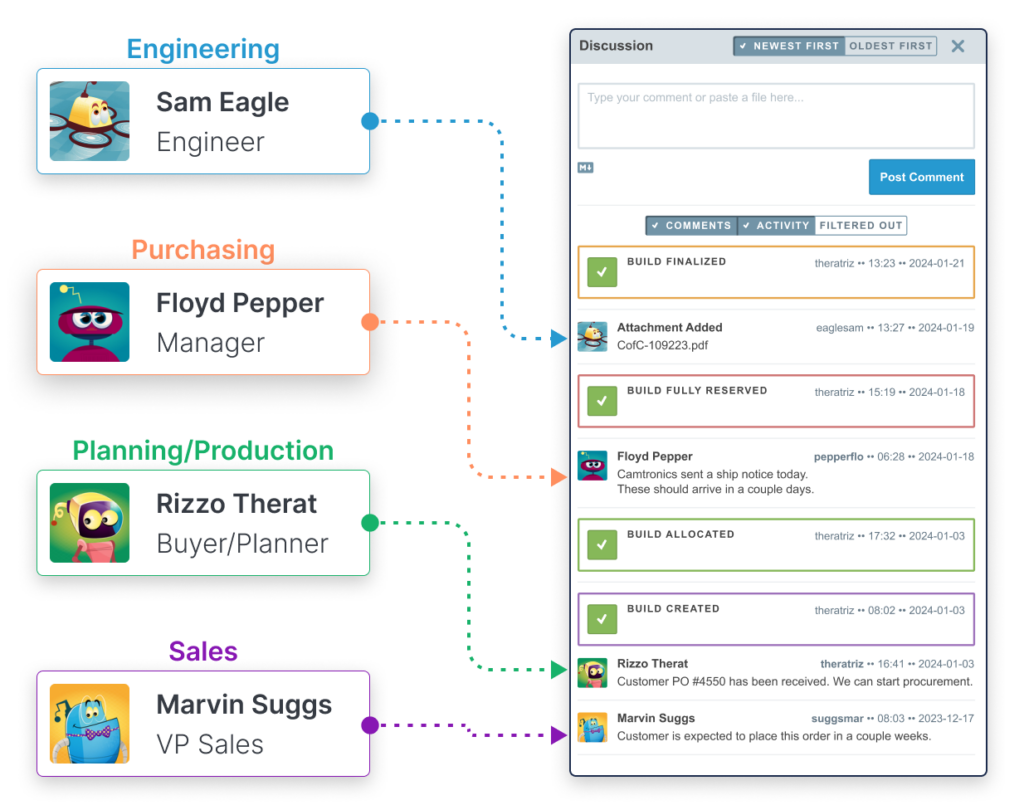

Using Aligni MRP as the communication hub between different departments enables real-time collaboration. Built-in communication tools such as comments, annotations, approvals, and notifications help streamline interaction within the application. This allows for faster decision-making, feedback, and problem-solving as the design group works together with manufacturing, engineering, and procurement teams simultaneously on a single platform. It also keeps everyone up to date.

Enhancing Communication and Visibility

The Aligni MRP system promotes transparency and visibility across the organization, enabling departments to understand the progress of products and production at each of their stages. The software makes it easier to enjoy effective communication by providing a platform where departments can share information, updates, and feedback. When every department knows what’s going on, operational lags, misunderstandings, and misinterpretations are reduced

Streamlining Change Management

During a production run, changes will happen to a product. Parts will change, designs will be updated and processes adjusted. Keeping track of those modifications is necessary to reduce errors, lost time, and rework or scrap. Aligni’s MRP system provides change management processes to effectively manage those events. The system’s ECM capability acts as the main switchboard for managing notifications to all stakeholders about proposed changes. Afterward, the software can record member’s feedback or approvals and update BOMs and builds. Aligni facilitates seamless collaboration between departments during the implementation of product changes. This streamlined approach minimizes delays, confusion, and rework.

Collaborative Workflow Management

Materials requirements planning software provides industry-supported best-practice systems for the definition and deployment of collaborative workflows. Different departments can define their respective tasks, responsibilities, and dependencies within the system, ensuring that each department’s role is clear, and the workflow progresses seamlessly. This structured approach eliminates manual handovers, reduces bottlenecks, and improves overall efficiency and productivity.

Connecting the Dots

Migrating to Aligni’s MRP system provides an integrated platform for all aspects of a manufacturing operation – including the firm’s data. The system enables work groups and departments to work together more efficiently, share information seamlessly, and make informed decisions.

If you’re looking to break down departmental barriers and foster collaboration in your organization, Aligni MRP can significantly improve supply chain and manufacturing processes.

It’s time to sign up for Aligni today.

Start your 30-day free trial

Join over 4,000 teams that are managing their manufacturing with Aligni.