MRP is ERP for Small and Medium-Sized Businesses

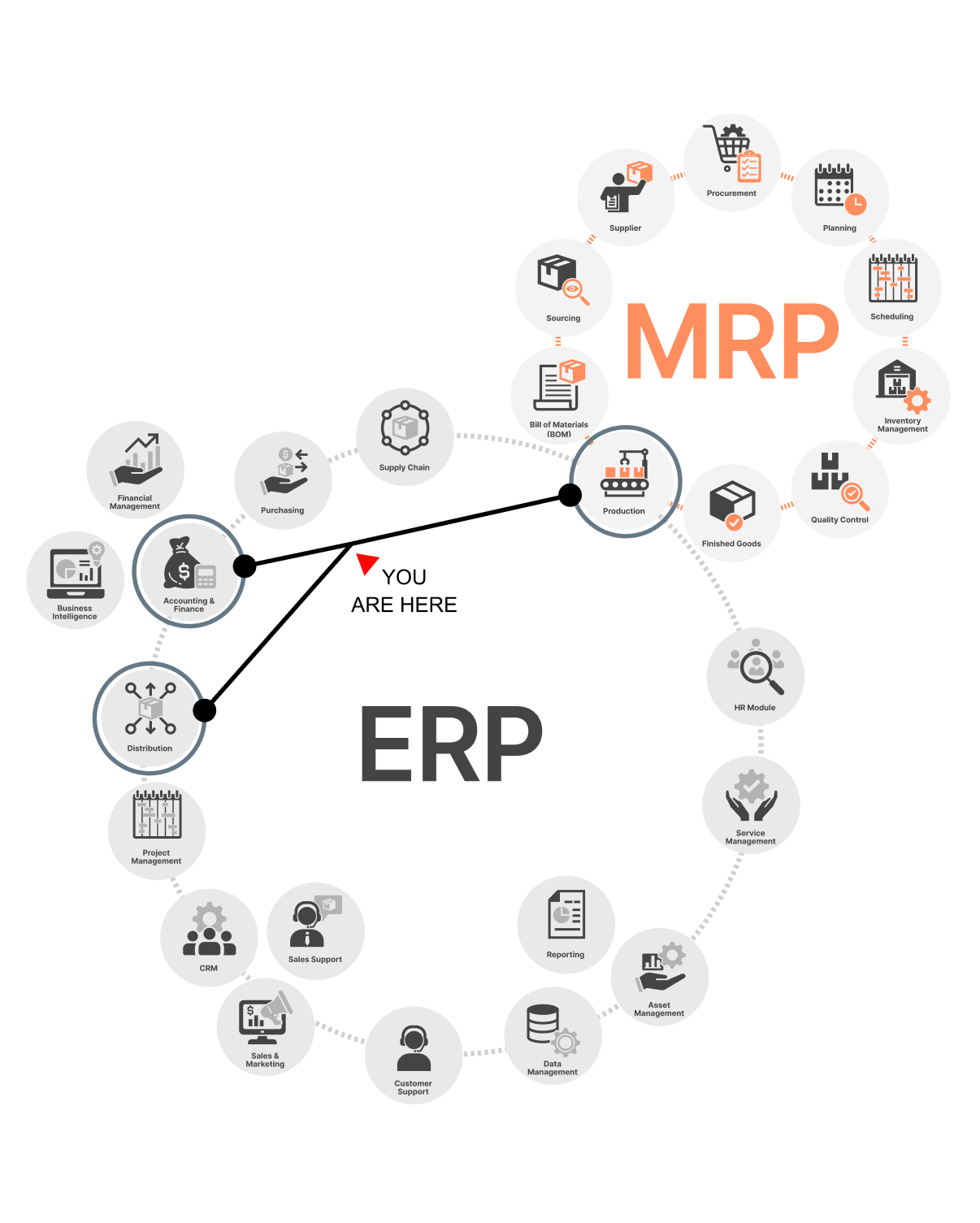

If your current challenges involve inventory, purchasing, and production — not HR, payroll, or tax compliance — a Material Requirements Planning (MRP) system may be the right fit for where you are now.

Rethink the Solution, not the Goal

Your business is growing. Simple things now take longer. Your accounting system wasn’t built to manage sophisticated, component-level inventory. Spreadsheets are harder to manage. Inventory is harder to track. Production delays are harder to avoid.

You may have considered, or had someone recommend, going with an ERP system. It promises full control across your organization but often brings a heavy lift, complex implementation, long timelines, and features you don’t need.

MRP gives manufacturers structure, visibility, and control, without the cost or complexity of enterprise systems. It’s a long-term investment that supports your current team and sets the stage for sustainable growth. All without replacing your existing accounting system.

Built for Today. Ready for What’s Next

Accounting software is good (enough) for finished goods inventory but… Material Requirements Planning software is designed specifically for manufacturing operations. It gives small and mid-sized teams the visibility and control they need to manage production without the overhead of full-scale ERP.

- Drive production from demand

- Track inventory at multiple warehouses or internal locations

- Manage multi-level BOMs, assemblies, and part alternatives

- Manage builds and production schedules

- Forecast demand and plan purchasing

- Visualize safety stock and material shortages

- True real-time costing – component + labor + overhead + etc.

- Lot / serial number traceability

Many manufacturers adopt MRP as their first structured system for inventory and production. It becomes the backbone of day-to-day operations and grows with them over time.

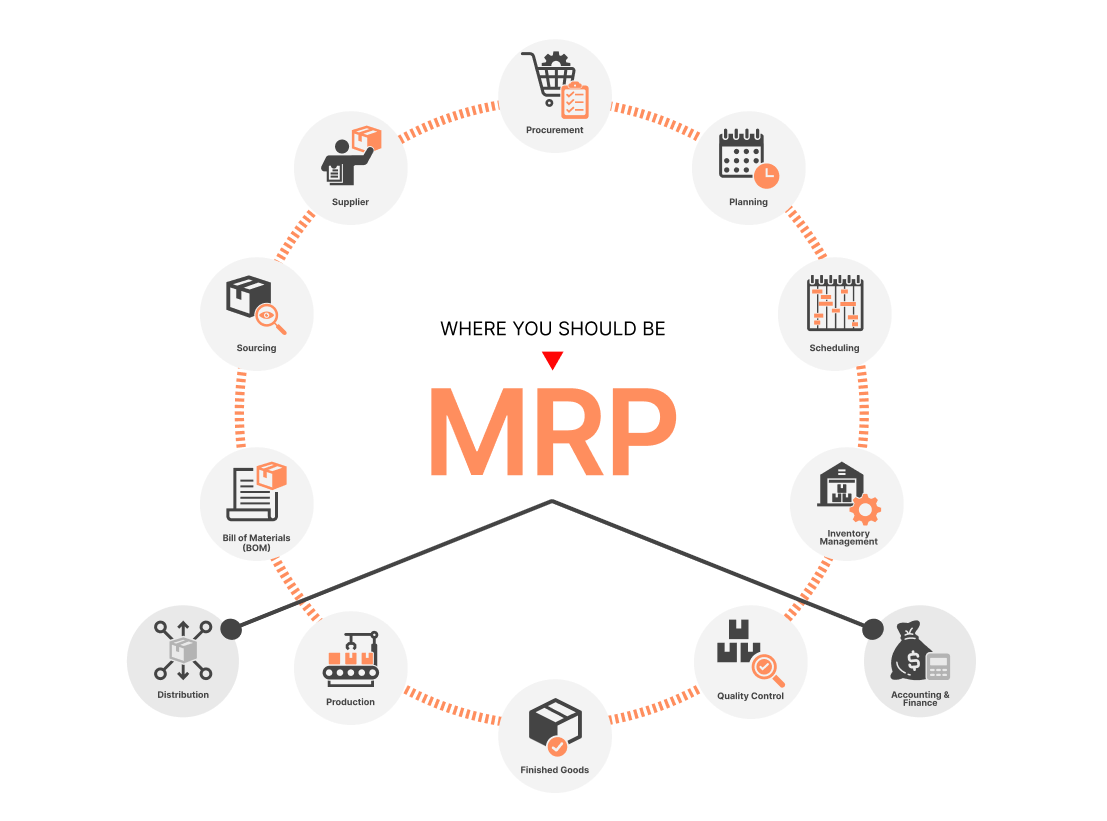

The Essentials You Need for Manufacturing.

Traditional ERP systems often require stitching together modules or hiring consultants to align the software with your business. Material Requirements Planning platforms take a different approach. They provide essential tools like inventory tracking, production scheduling, demand forecasting, purchasing, and quality control in one fully integrated platform. Lower cost. Less complexity.

MRP systems are built for real manufacturing workflows. They are easy-to-adopt, quick to set up, and intuitive for teams to use. You won’t need third-party integrations or a drawn-out onboarding process to get started.

This isn’t a temporary fix. For many companies, it’s the foundation that supports the next 5+ years of growth and beyond.

What is MRP as ERP?

MRP delivers roughly 90% of the ERP capabilities manufacturers truly need today—without the cost, disruption, or overhead. Aligni replaces spreadsheet chaos and disconnected systems with a focused, connected platform for managing inventory, planning, and production.

You don’t need a dozen modules. You need the right tools, right now, to keep your team aligned and your builds on track.

Get Up and Running in Hours, Not Months

MRP systems are designed for speed. There’s no need for custom integrations, extensive configuration, or an IT team to run implementation. Most manufacturers are up and running in a matter of days.

Because the platform is cloud-based and fully integrated, setup is streamlined. You can start using it without disrupting your workflow or waiting on consultants.

This is a common first step for teams that need to stay agile while gaining structure.

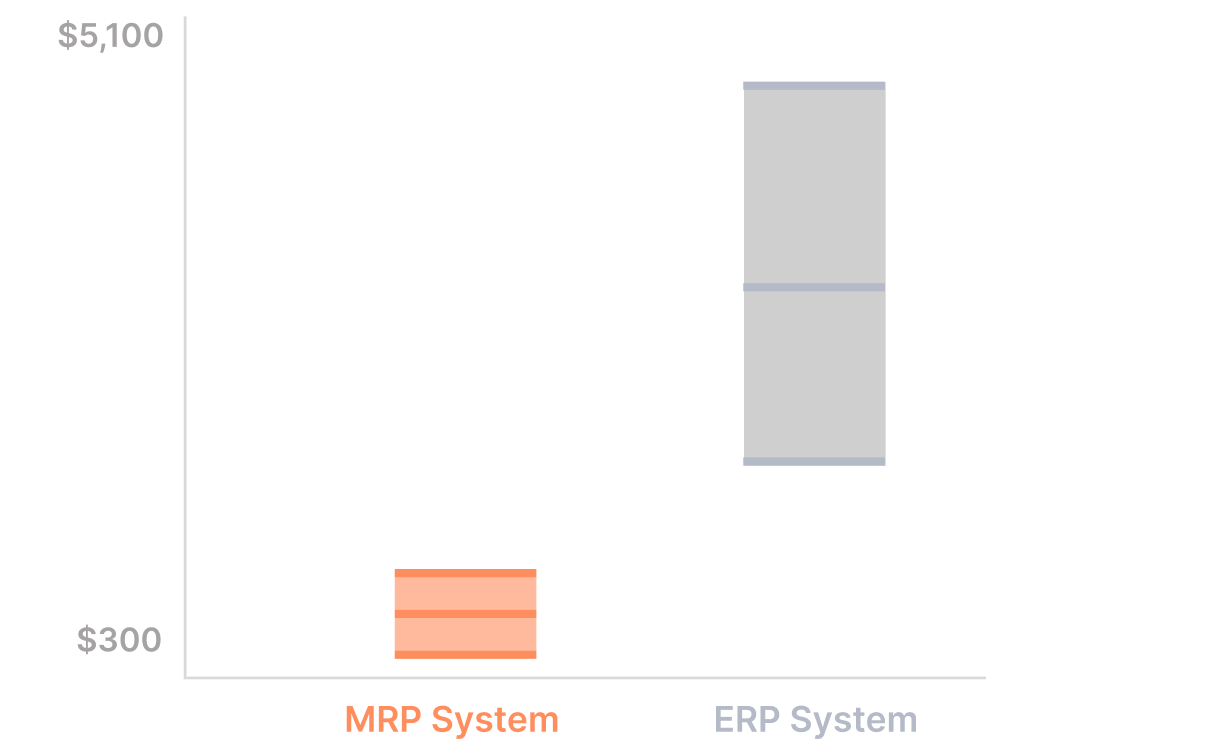

Transparent Pricing That Grows With You

One of the biggest frustrations with ERP systems is unpredictable pricing. Features are gated behind modules, integrations cost extra, and you often need a sales call just to get a quote.

Material Requirements Planning systems keep it simple. Pricing is transparent and based on what you actually use. There are no hidden fees, no complicated packages, and no surprises as your team grows.

Budgeting becomes easier. Planning becomes smarter.

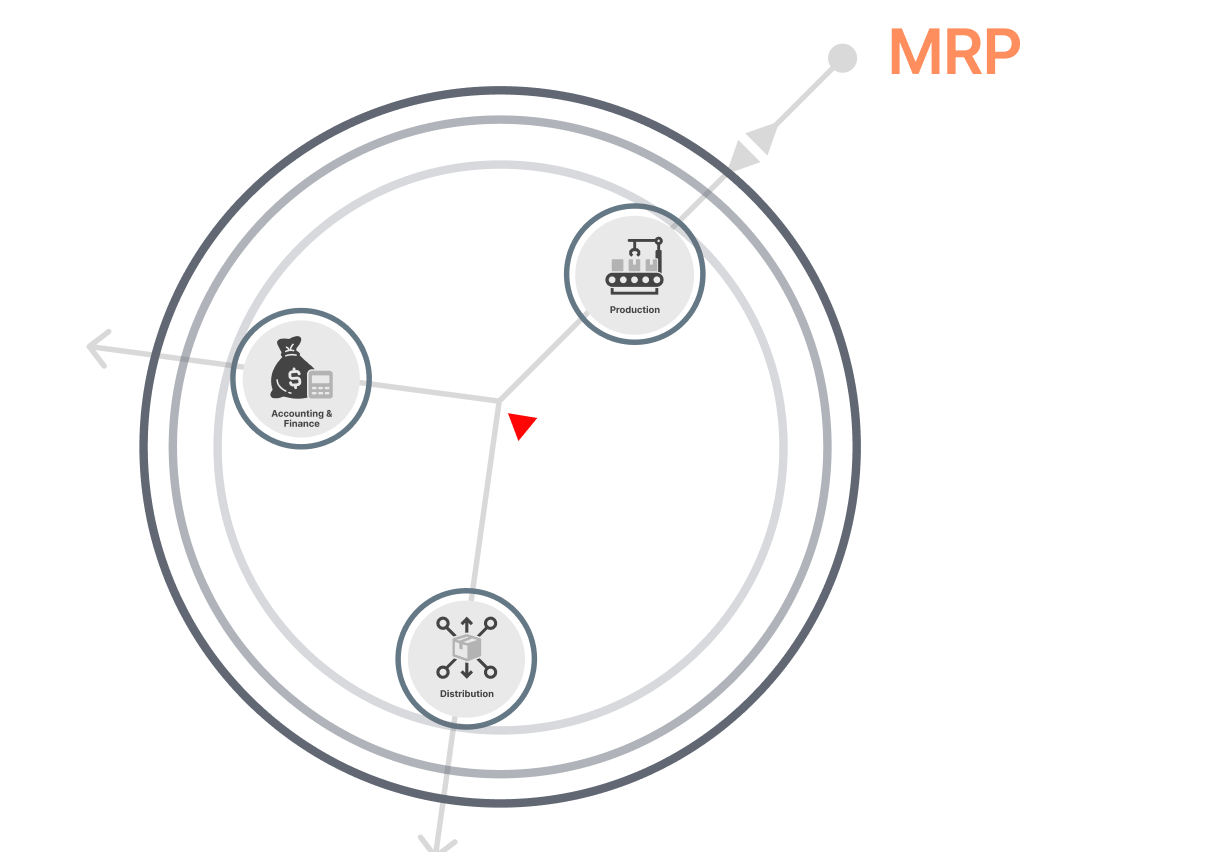

Keep Your Accounting,

Gain Manufacturing Control

A modern MRP sits on top of your existing general ledger — pushing finished-goods, cost of goods sold, and inventory adjustments straight back into your books — while handling everything production-side.

No massive data migrations, no retraining your finance team on a new ERP module.

MRP fills in those gaps — without replacing the finance stack you rely on today. It’s a lightweight overlay that delivers deep manufacturing visibility and keeps your day-to-day financials exactly where they belong.

What to Look for in a Material Requirements Planning System

A strong MRP system should include the features you need to manage production effectively. These are the core capabilities every solution should deliver:

Start your 30-day free trial

Helping You Make Great Things…Better.