Product development and management processes have a lot of moving parts to oversee and there’s a lot riding on things going well. Many times, smaller companies and hobbyists often try to manage their BOMs and revisions using file system organizations and spreadsheets or even “smart spreadsheets” such as Airtable, Notion, etc. As the complexity grows, the need for a more sophisticated system arises.

When production ramps up or processes get more complex, it’s time to step back and notice things need to change to help facilitate growth. If you’ve gotten to this page, then you’re probably aware that a little help is needed and you may have very specific issues your homegrown process is lagging at. Maybe your firm needs to manage that process with a better system than spreadsheets. A PLM could be that solution.

But First, What Is a PLM System?

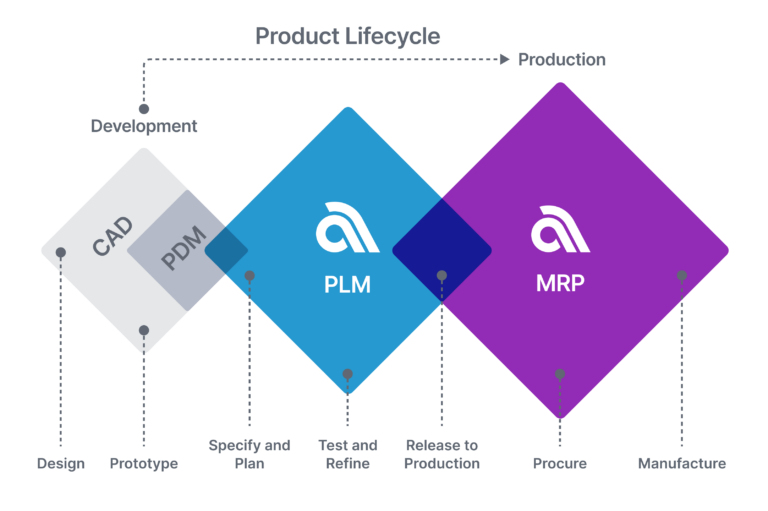

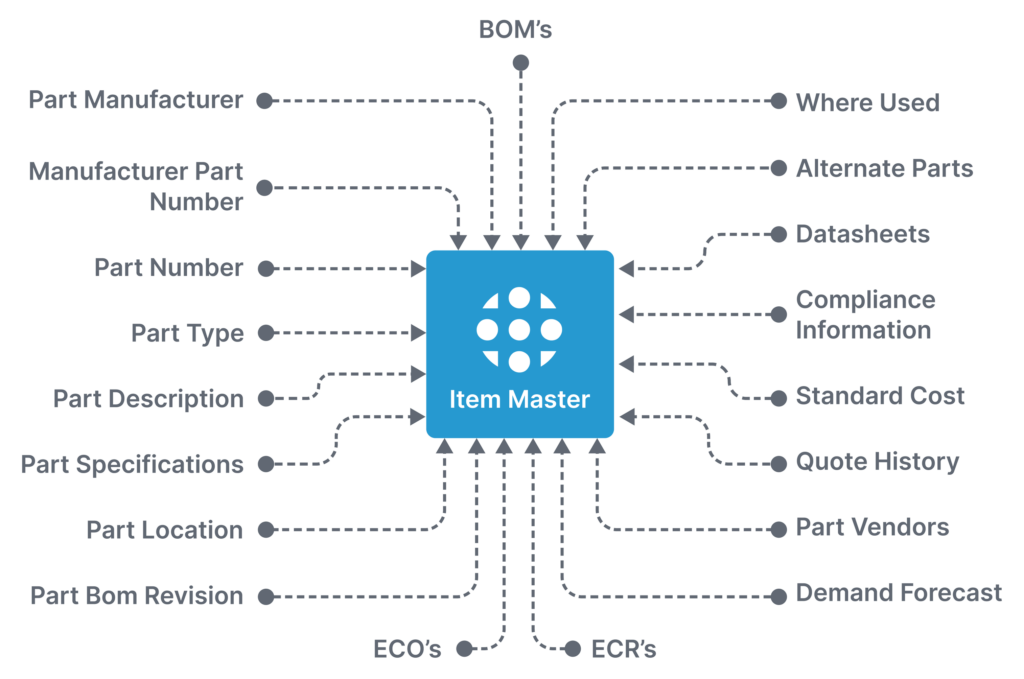

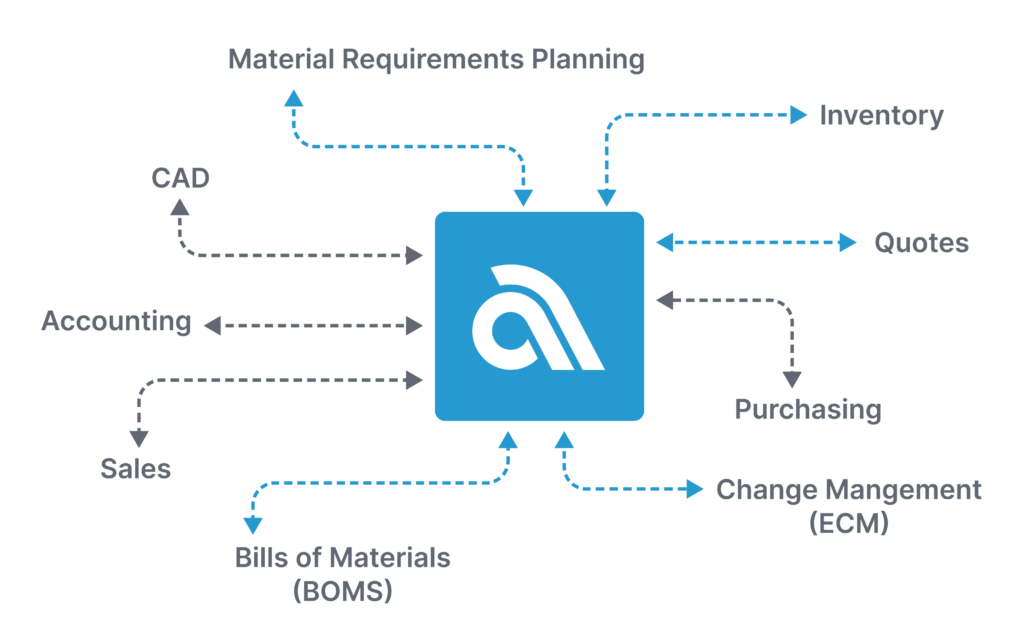

A Product Lifecycle Management (PLM) system is a comprehensive software solution that facilitates the end-to-end management of a product’s lifecycle, from its initial concept and design through manufacturing, distribution, and eventual retirement. It acts as a centralized platform, enabling efficient collaboration among teams, storing and managing product data, streamlining processes, and providing real-time visibility into the entire product development journey. By integrating various product-related tasks and workflows, a PLM system helps companies optimize productivity, reduce time-to-market, ensure regulatory compliance, and improve product quality and innovation.

Where Will a PLM System Help Us?

Companies tend to adopt a PLM system for a variety of initial reasons. It usually starts with solving a specific pain point. A company should consider implementing a PLM system, like Aligni when it faces challenges related to product complexity, collaboration, data management, regulatory compliance, supply chain efficiency, time-to-market, quality control, or cost optimization. Here are some common indicators that a company could benefit from implementing a PLM system:

Increasing Complexity of Products

As products become more complex, managing their development, design, and manufacturing processes becomes more challenging. This is necessary in environments where there are a number of engineering groups specifying components and processes that will need to be integrated into the final product. High part count products tend to need specialized software to manage large bills of materials, especially when parts require stringent specifications. A PLM system can help handle the growing complexity by providing a centralized platform for interdepartmental collaboration, part data and specification management.

Frequent Product Updates or Introductions

If a company is regularly updating existing products or launching new ones, a PLM system can help streamline these processes. Industries that require quicker time to market or manage products with a large number of variants all but require PLM software to keep versions compartmentalized. It ensures that all teams have access to the most up-to-date information and enables faster decision-making, reducing time-to-market.

Data and Document Management Issues

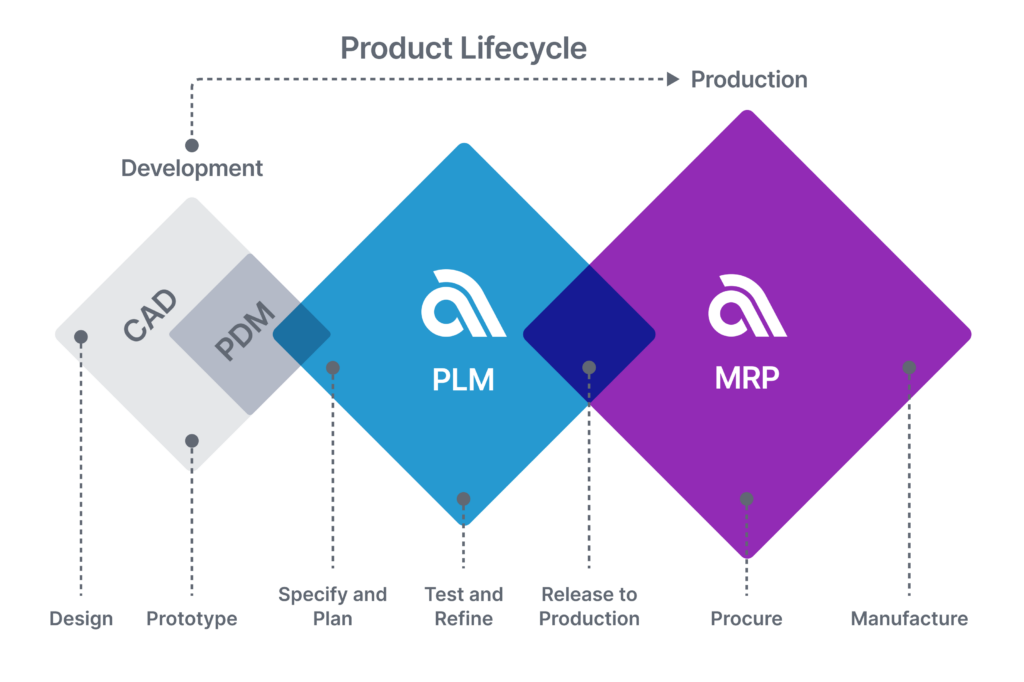

When product data, documents, and design files are scattered across various systems and locations, it can lead to inefficiencies and errors. A PLM system offers a single source of truth with its item master database. This simplifies data management and reduces the risk of using outdated or incorrect information circulating in product management operations.

Regulatory Compliance Requirements

Companies operating in regulated industries may face strict compliance standards. These regulations and certifications need to be stored, managed and updated ideally in a secure, centralized location for day-to-day adherence and audit situations. A PLM system can help ensure that products meet these requirements, making it easier to track and manage regulatory data.

Need for Innovation and Speed-to-Market

A company aiming to stay competitive in a fast-paced market may require a PLM system to help accelerate innovation, reduce time-to-market, and respond quickly to customer demands. The system does this by streamlining the product development process, from easing part specifying and overseeing product revisions to smoothing the handoff process to manufacturing.

High Product Development Costs

Inefficiencies in product development can lead to increased costs. Implementing a PLM system can optimize processes, reduce waste, and enhance resource allocation, resulting in cost savings. This can be found through streamlined specifying and more efficient purchasing operations and a reduction in operating with outdated or siloed data.

Communication and Collaboration Challenges

If different teams, departments, or external partners struggle to communicate effectively during the product development lifecycle, a PLM system can improve collaboration by facilitating data sharing, feedback, and seamless communication. The PLM system acts as the hub for information and communication between work groups, departments and even vendors.

Bringing It All Together

If your issue is on this list, then it’s time to look deeper at adopting a product lifecycle management system. While rolling your own system with spreadsheets or custom coding is an option, a purpose-built PLM system can be a valuable investment that leads to increased productivity, innovation, and competitiveness in the market. Dedicated PLM systems are built from the best practices developed from thousands of implementations. Riding this wave of evolution means you don’t have to expend the energy to re-invent a product management system to get these results. Instead, your company can use that potential investment to move further down the path of efficient, optimized success.

Want to get a deeper dive on PLM systems? With our data-filled online demo system and thirty-day free trial period, you can see how Aligni can streamline your product management processes. It’s time to sign up for Aligni PLM today!

Start your 30-day free trial

Helping You Make Great Things…Better.