As we continue to improve Aligni, our focus remains on helping manufacturers optimize processes, gain better visibility into their data, and adapt to real-world production needs. This quarter’s updates reflect direct feedback from our users—delivering more control over costs, more flexibility in inventory management, and faster ways to navigate and share information.

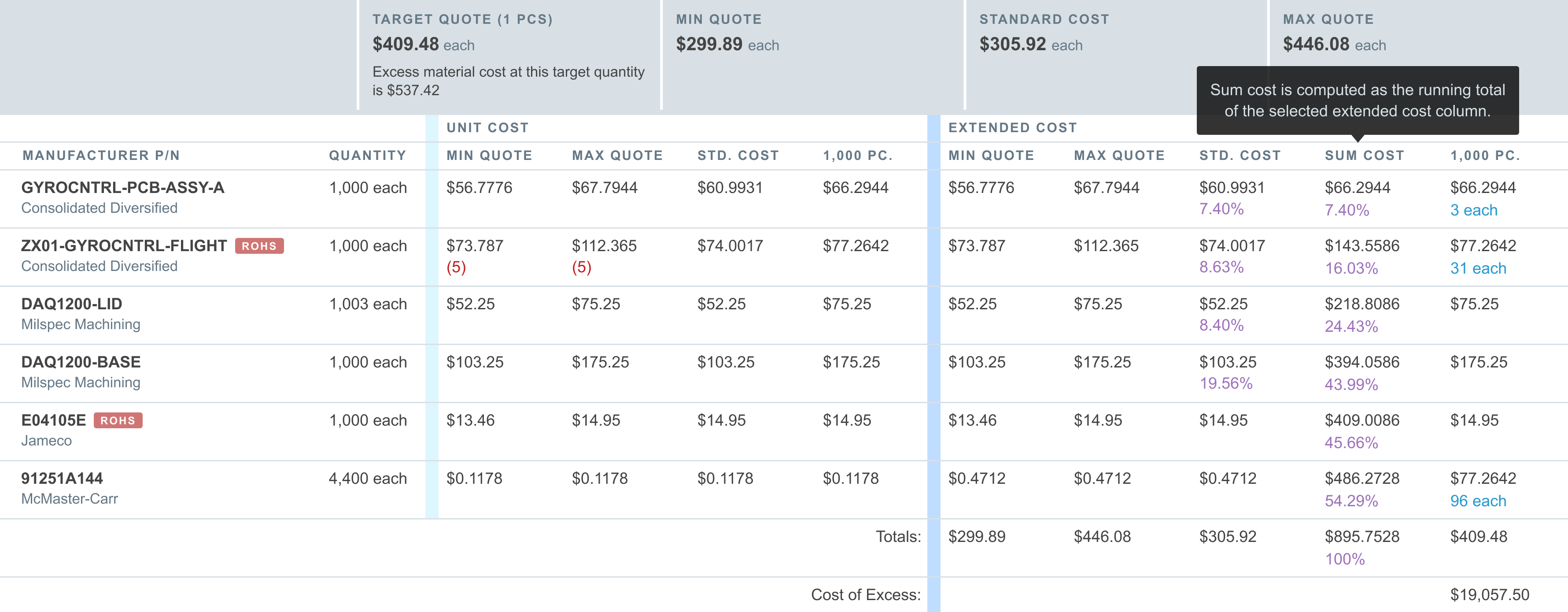

Enhanced BOM Cost Sheet

We’ve made important improvements to the BOM cost sheet to help planners better understand and manage cost drivers within their assemblies.

- Sum Cost Column: Adds a running total alongside each row in the BOM, making it easy to identify which components contribute most significantly to overall cost.

- Percentage Contribution: Displays each item’s relative impact on the total cost, allowing for more informed decisions about potential adjustments or substitutions.

Combined with enhanced sorting capabilities, these updates make it easier to focus on the most critical cost factors.

Learn more about BOM Cost Sheets →

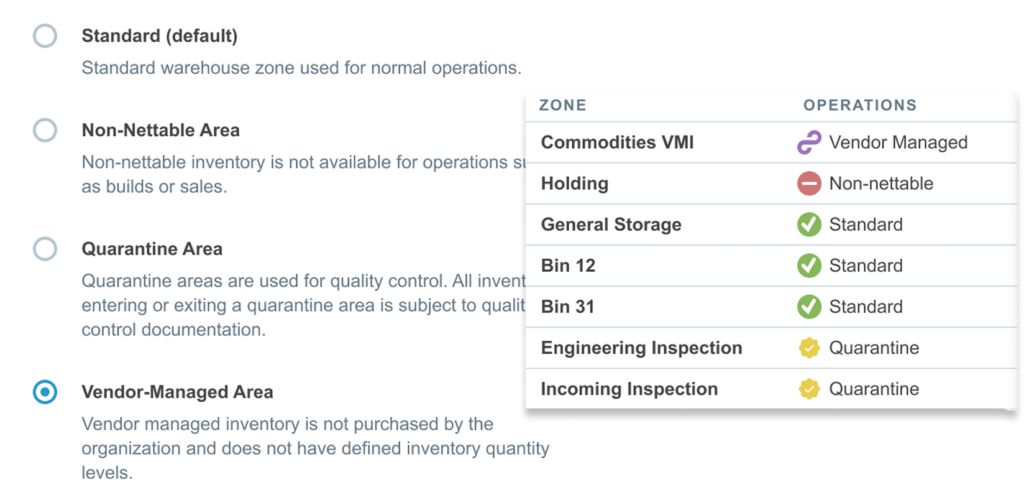

New Warehouse Categories for Greater Flexibility

To support the diverse inventory management needs of manufacturers, we’ve introduced two additional warehouse types: Vendor-Managed Inventory (VMI) and Non-Nettable Inventory.

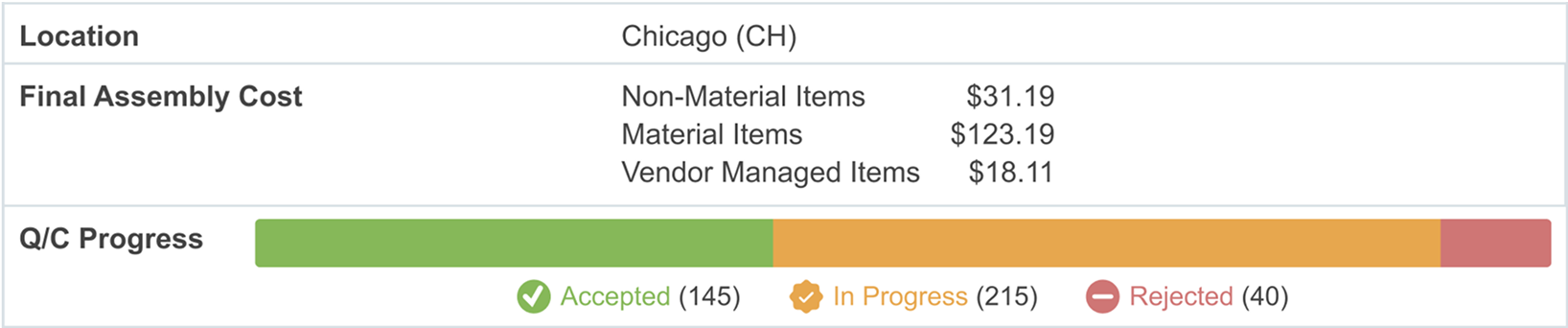

Vendor-Managed Inventory (VMI)

VMI is ideal for situations where material availability is maintained by a partner or supplier, rather than being tightly controlled internally. VMI can also be useful for high-volume or commodity items like adhesives, fasteners, and other consumables where procurement processes are non-standard.

VMI attributes and behavior includes:

- Items are either available or not available, but no quantity is associated with them.

- Items are available for use in builds but are never depleted.

- VMI can be used alongside standard inventory, even within the same build or warehouse.

- Costs are still tracked and included in finished goods, with VMI called out separately on build cost ledgers.

Non-Nettable Inventory

Non-nettable stock is intentionally excluded from builds, forecasts, and material shortage reports. It’s physically present, but not available for production. Common uses of non-nettable inventory include:

- Defective or damaged parts

- Items held on consignment or owned by third parties

- Reserved or restricted stock

- Goods still in transit

This category allows greater control over what inventory is considered active and available in planning processes.

Learn more about Non-Nettable Inventory →

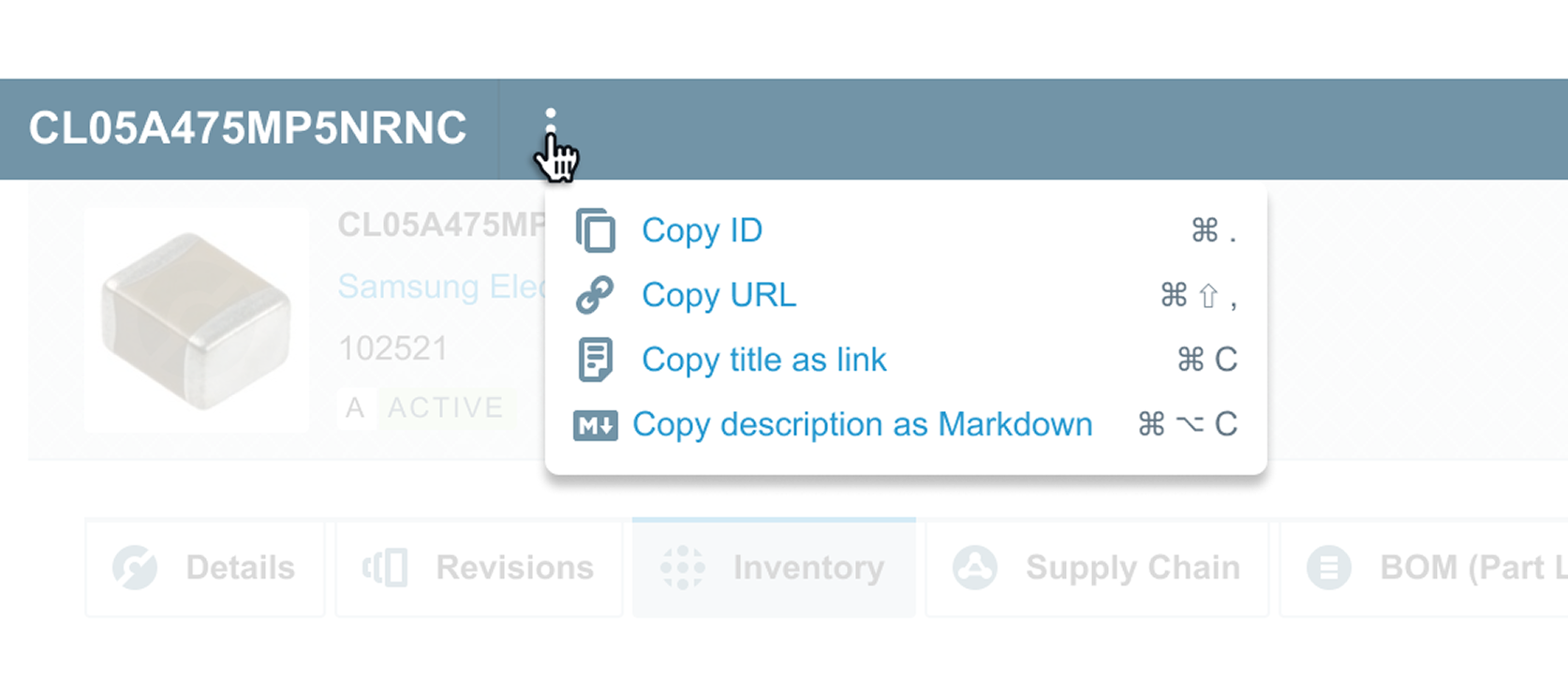

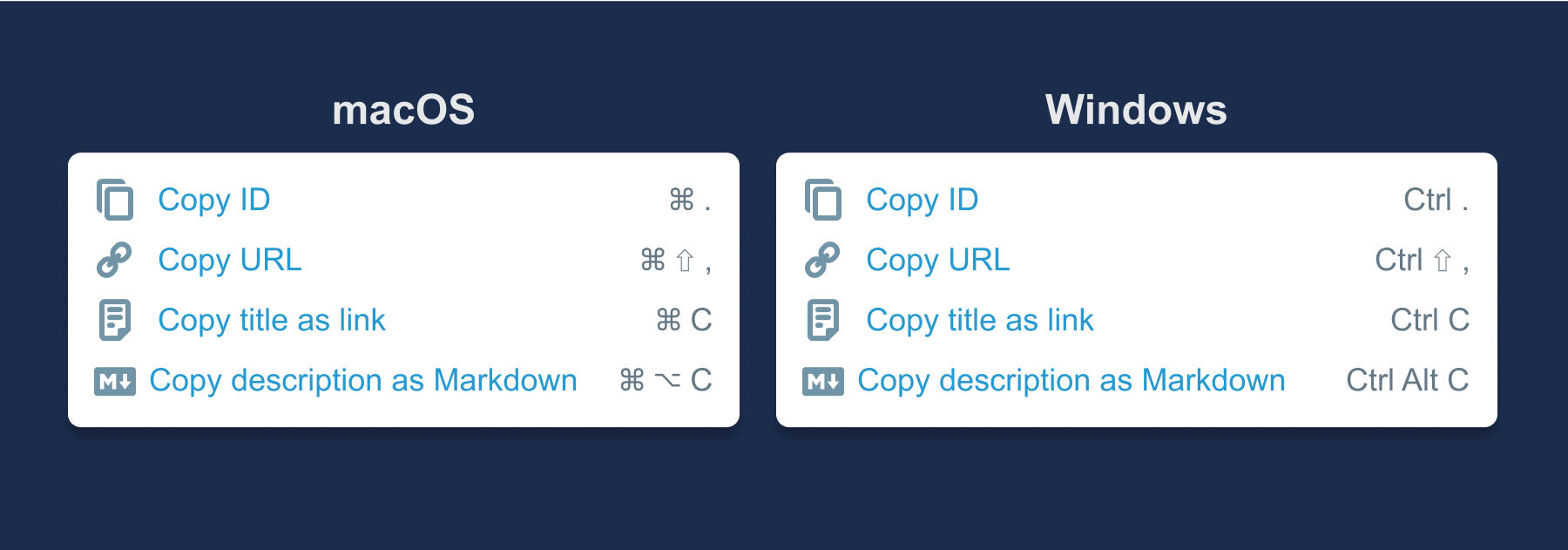

Global Record Menu for Quick Access

Efficiency often comes down to the small details. Our new quick actions menu allows you to quickly copy and share key record information.

- Easily copy raw IDs, Markdown-formatted links, or URLs.

- Designed for seamless integration into documentation, support tickets, or communications with your team.

This feature is ideal for teams who need to move quickly between tools and processes without losing time formatting or searching for data.

Additional Improvements

We’ve also introduced a number of smaller enhancements aimed at improving everyday usability:

- Smarter Sort & Filter Tools – Enhanced filtering and sorting to help you locate key data quickly, whether you’re analyzing high-cost items or refining lists.

- Refined Record Headers – Updated layouts across more pages, allowing you to identify important information at a glance.