When your organization is small, you can get away with using general tools for managing operations like spreadsheets or email clients. You’re also small enough where there’s not a lot of people in the office to interact with or production volume to manage. That makes it easy to understand what is going on and who has the latest info.

As an organization grows – both internally and with external resources, those homegrown management tools and tight-knit offices tend to lose their effectiveness under the strain of more data, people, and production to oversee. There may not be an exact point where a company learns it’s time to start moving to a more ‘corporate’ method of operation, but the organization quickly figures out when it has blown past that point.

The best move for a company at this stage is to upgrade to a purpose-built business system that can effectively manage its data and to make that data accessible to the right people in the organization. While many companies initially explore ERP systems, for small and medium sized businesses that manufacture products, the best solution is a materials requirements planning system.

An MRP System Defined

In a basic sense, a Material Requirements Planning (MRP) system is used in manufacturing to ensure materials and components are available for production, products are completed on schedule, and inventory levels are effectively managed. The system typically relies on three primary inputs:

- Demand planning and scheduling which details what products need to be manufactured and when.

- The product’s bill of materials (BOM), a comprehensive list of raw materials, components, and assemblies required to create a product; and

- The company’s inventory records, which track the availability of materials and finished goods.

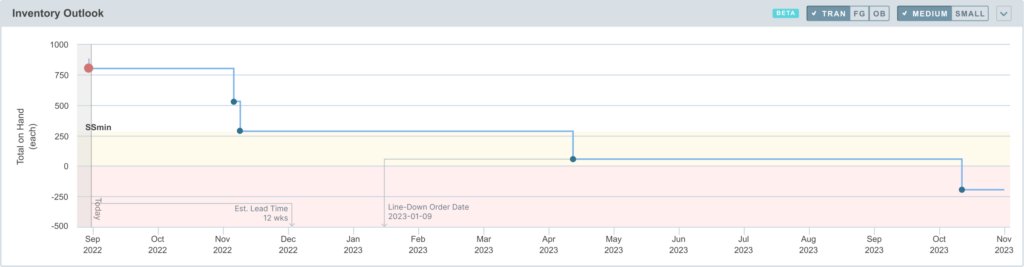

Day-to-day, the MRP streamlines the understanding of factors such as lead times for ordering and production, current inventory levels, and supplier constraints to generate recommendations for production planning, purchasing, and inventory management. By analyzing these inputs through the lens of the MRP’s rich tool sets, the company determines what materials are needed, the quantities required, and when they should be ordered or produced to meet production deadlines.

While the basic functionalities described above helps companies manage their operations effectively, the ability of MRP systems like Aligni to collate and share information across the entire company is what helps manufacturers streamline their operations, minimize delays, and reduce excess inventory costs.

Working from a Singular Data Source

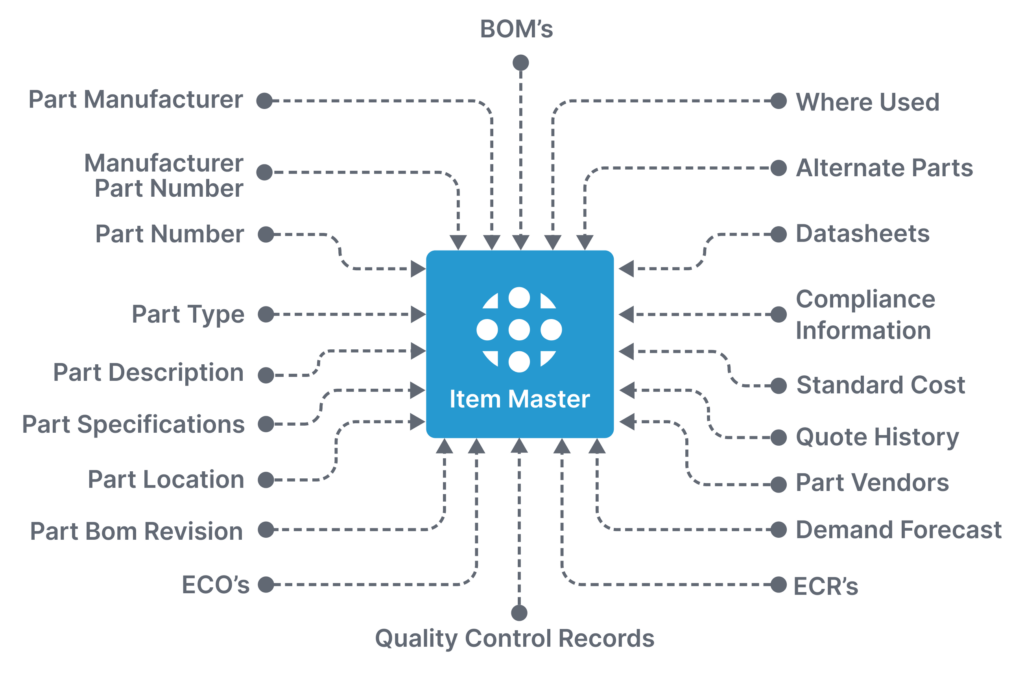

The biggest benefit from moving to an MRP system is creating a single source of truth for the organization instead of continuing to propagate the building of departmental data silos. Aligni MRP is built on a database that stores all the company’s information within it. Aligni’s database structure allows every department in the organization to store their information in the system in a manner that not only makes sense for their processes but also makes it sharable to others in the organization. The centralized database also reduces the barriers to combining interdepartmental data in new ways that provides even greater value for the departments and the company as a whole.

This centralization of information ensures the organization is working off of a single source of truth rather than an amalgamation of siloed data structures that may or may not be up to date or even correct. Since everyone in the organization is pulling from the same database, it can be assured that the information accessed is not only as current as possible but the same as the data other departments are using to make decisions with. For example, when Purchasing requotes a component and inputs the new cost structure into Aligni, it is updated for the engineering department immediately, ensuring their bills of materials are current to the latest pricing information – no meetings, calls or emails are needed to double-check.

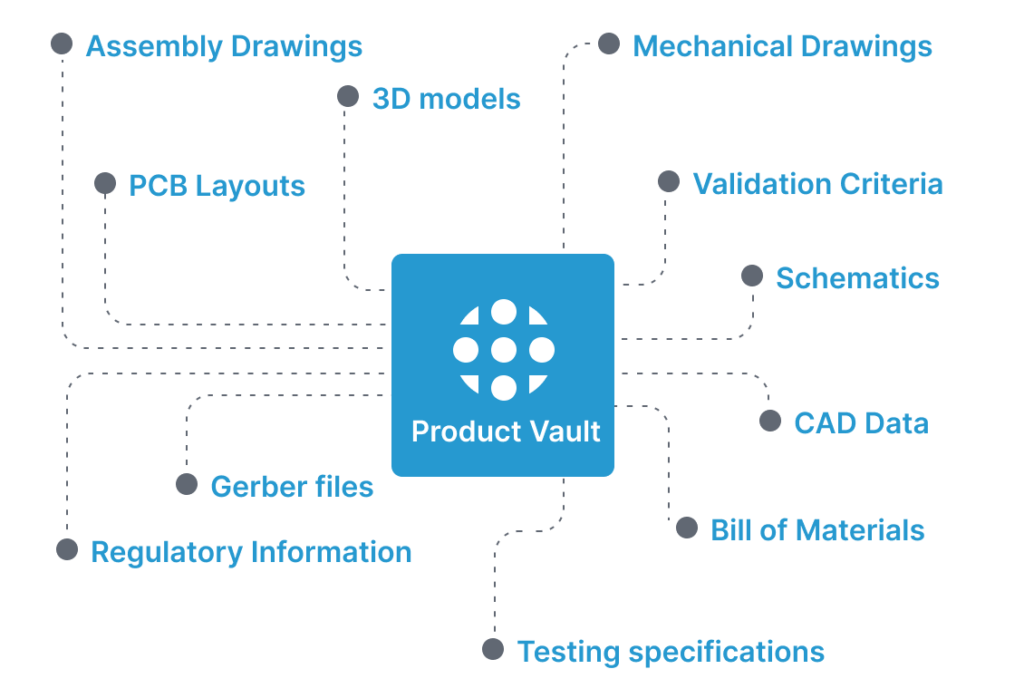

Extend and Control Data Sharing with External Vendors

Extending the single source of truth further, Aligni MRP provides the opportunity to share information with vendors stored within the system. Information stored within Aligni’s database can be selected and compiled into vaults that can be securely shared with specific vendors. This ability not only ensures vendors are receiving the latest approved information on products but it keeps vendors informed when changes to these shared files occur with notifications sent when changes have been made to the files provided within the shared vault. No more tracing part files from engineering to purchasing and to vendors or tracking revision levels for everything sent. Aligni provides this capability internally to the files stored within its database.

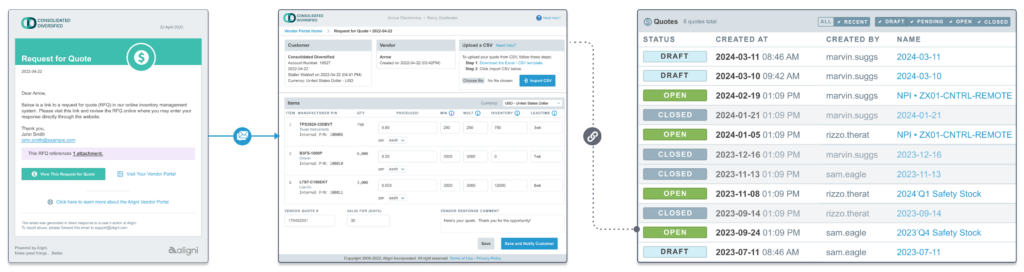

Using Aligni as your hub provides even greater collaborative capabilities. It provides the ability for vendors to interact with the system. Through Aligni’s ActiveQuote, vendors can directly input their pricing and delivery information into the system. This ability reduces the time and interaction needed for quoting and ordering components. It also reduces the potential for errors from re-keying information from emails and other vendor correspondence.

Built-in Collaboration with DiscussAnything

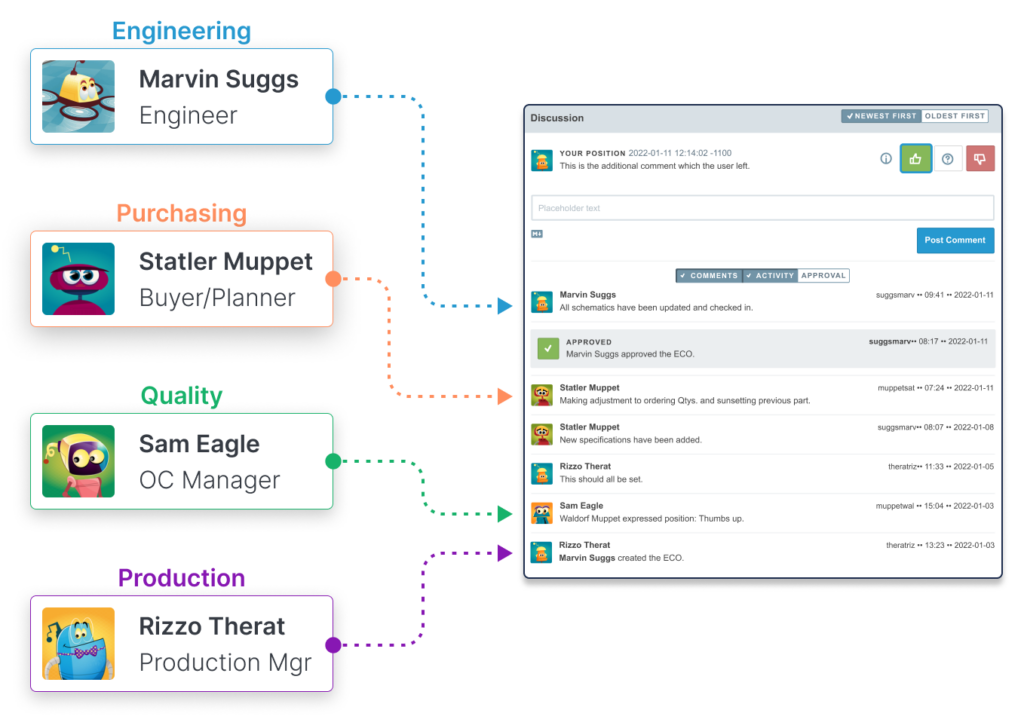

Many MRP systems are adept at purely managing files and data needed for production. Aligni provides greater value by becoming the centralized location for the conversations and knowledge that goes into making important decisions within the organization.

Aligni’s DiscussAnything capability is a robust discussion system that allows stakeholders across the organization to provide valuable input and receive updates on important issues the company faces. These conversations are affixed to items and processes contextually within the MRP system. Being highly integrated with the data and processes stored within Aligni, DiscussAnything is adept at reducing the time it takes to build consensus on important decisions facing the organization.

The conversations contained within DiscussAnything continue to provide value well past when the initial issue is resolved. These conversations are saved within Aligni’s database and linked to the parts and processes they shaped. Being able to revisit these conversations helps share tribal knowledge between departments while making the reasoning process for these decisions available for similar future projects, reducing double work and helping ensure better decisions are made based on prior knowledge and experience.

Notifications That Connect People to Processes

Aligni MRP provides a rich notification system that helps keep employees and vendors in the loop and critical processes moving forward. These email notifications trigger directly from the processes being worked on and lead back to those very same areas, ensuring a single, interconnected point of focus for the organization.

Aligni notifications are set to be sent when specific events happen, including at points within the ECM process, certain build management operations, and vendor actions including invitations to quote and when POs have been issued, to name a few. The company retains the ability to determine who receives the notifications and for what, ensuring those who need to know have access and are being alerted when conditions change or need attention – all without leaving the system to do it.

Members of the organization can also receive notifications of developments within the DiscussAnything sections they are participating in. This adds another dimension of utility to Aligni’s discussions capability, providing users with timely updates to changes in whatever process is being worked out and a quick method to return to the conversation. The notifications increase the speed of participation, streamlining decision making in the organization.

The Other Benefits of Making Aligni Your Business Hub

While the migration to Aligni MRP provides the collaborative and communicative benefits of a singular business system for manufacturers listed here, it also provides even greater value when taking into consideration the core capabilities of the MRP system and their effectiveness in smoothing workflows and extracting greater value from the data you already collect.

Learn more about what Aligni MRP can bring to your organization or simply sign up to start enjoying the benefits today!