Built Different

Most manufacturers manage part data in spreadsheets or bloated ERP systems that weren’t built for agility. Spreadsheets go stale. Big systems take months to implement. Either way, your data is disconnected from the work it drives.

Aligni is different. We give you a dedicated part management system built for modern manufacturing—fast to set up, easy to use, and powerful where it counts.

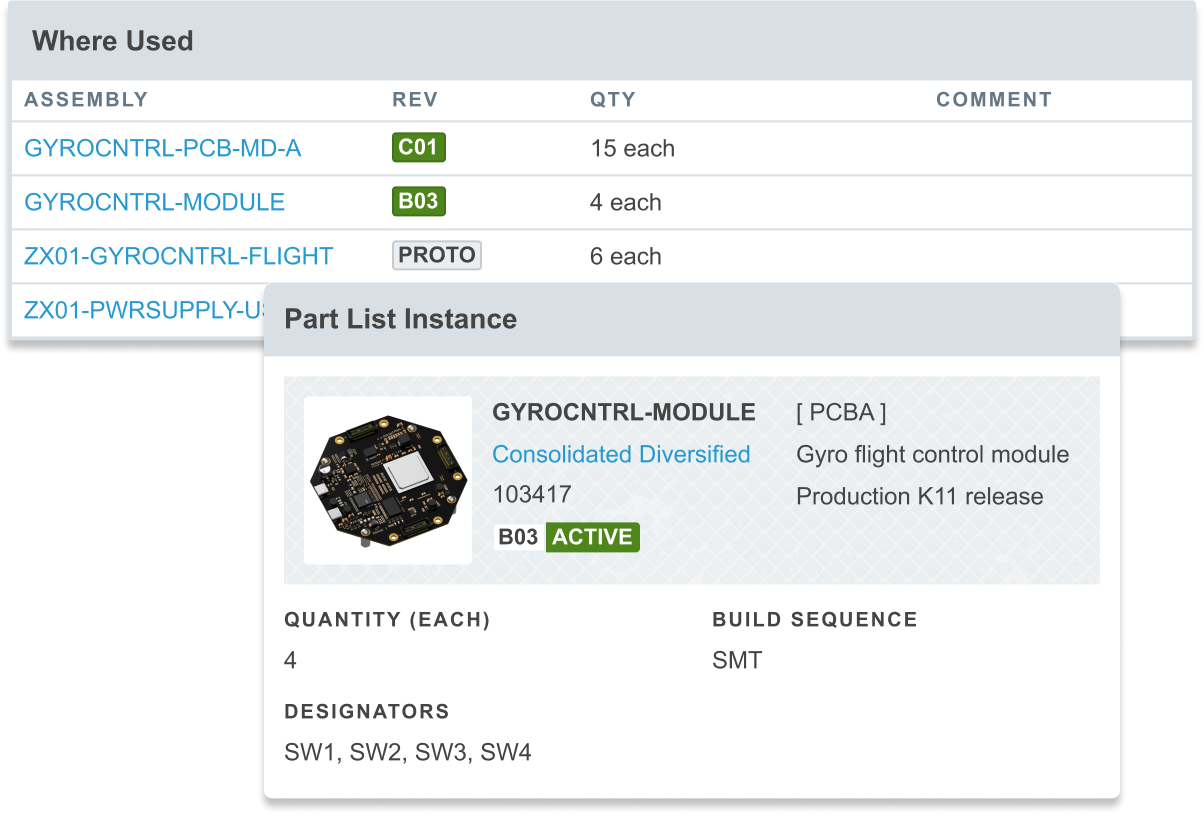

Know the Impact of Every Part with Where Used

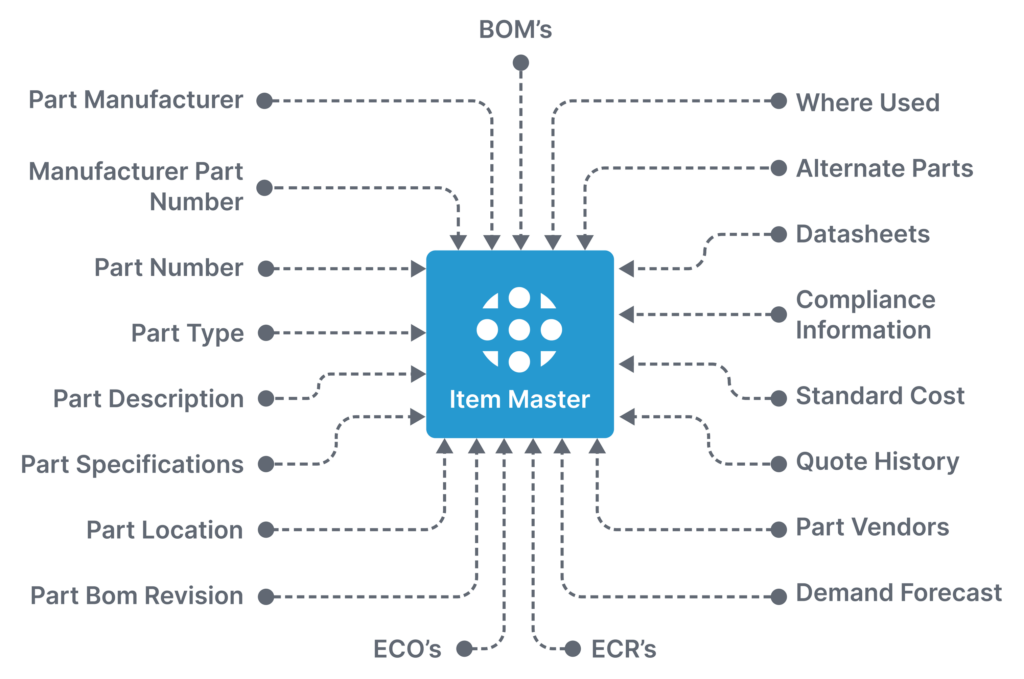

Your parts database isn’t just a list—it’s the foundation for builds, purchases, planning, and change management. Aligni’s item master connects every part to the workflows it drives.

- Build a trusted source of truth across engineering and operations

- Link data to BOMs, vendors, inventory, and builds automatically

- Empower faster decisions with complete part-level visibility

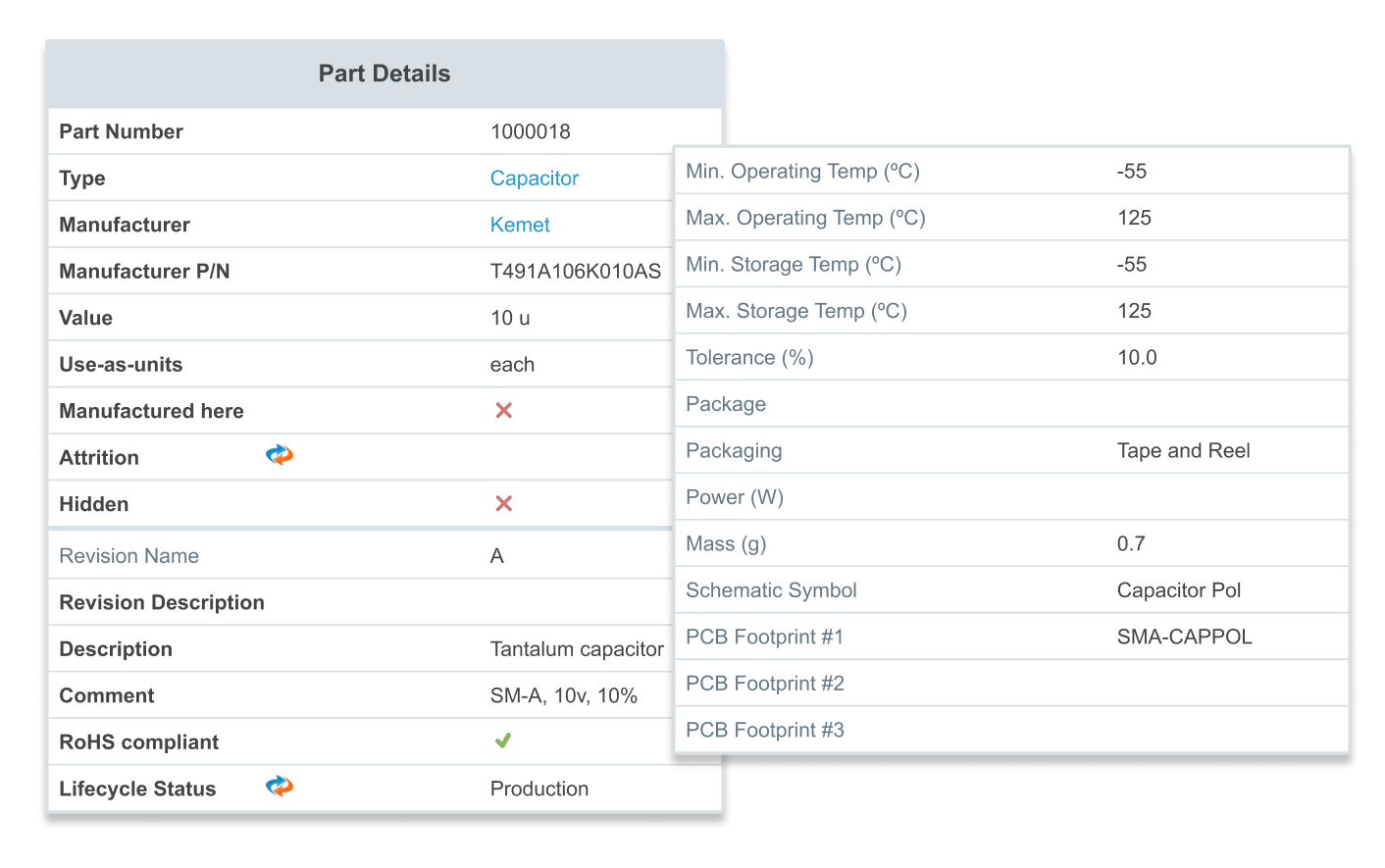

Customizable Part Attributes

Not every team tracks parts the same way. That’s why Aligni supports custom parameters, part collections, and rich metadata that flex to your process.

- Add internal specs, compliance tags, temperature ranges, and more

- Group parts by function, sourcing strategy, or product family

- Filter, sort, and search based on the data that matters most

What Is an Item Master in Manufacturing?

A item master is the complete data record for each component used in your products. It includes every detail—from the part number and description to preferred vendors, alternates, lead times, and where the part is used.

In Aligni, the item master isn’t just a list. It’s a dynamic hub that links part data to BOMs, builds, purchases, and planning.

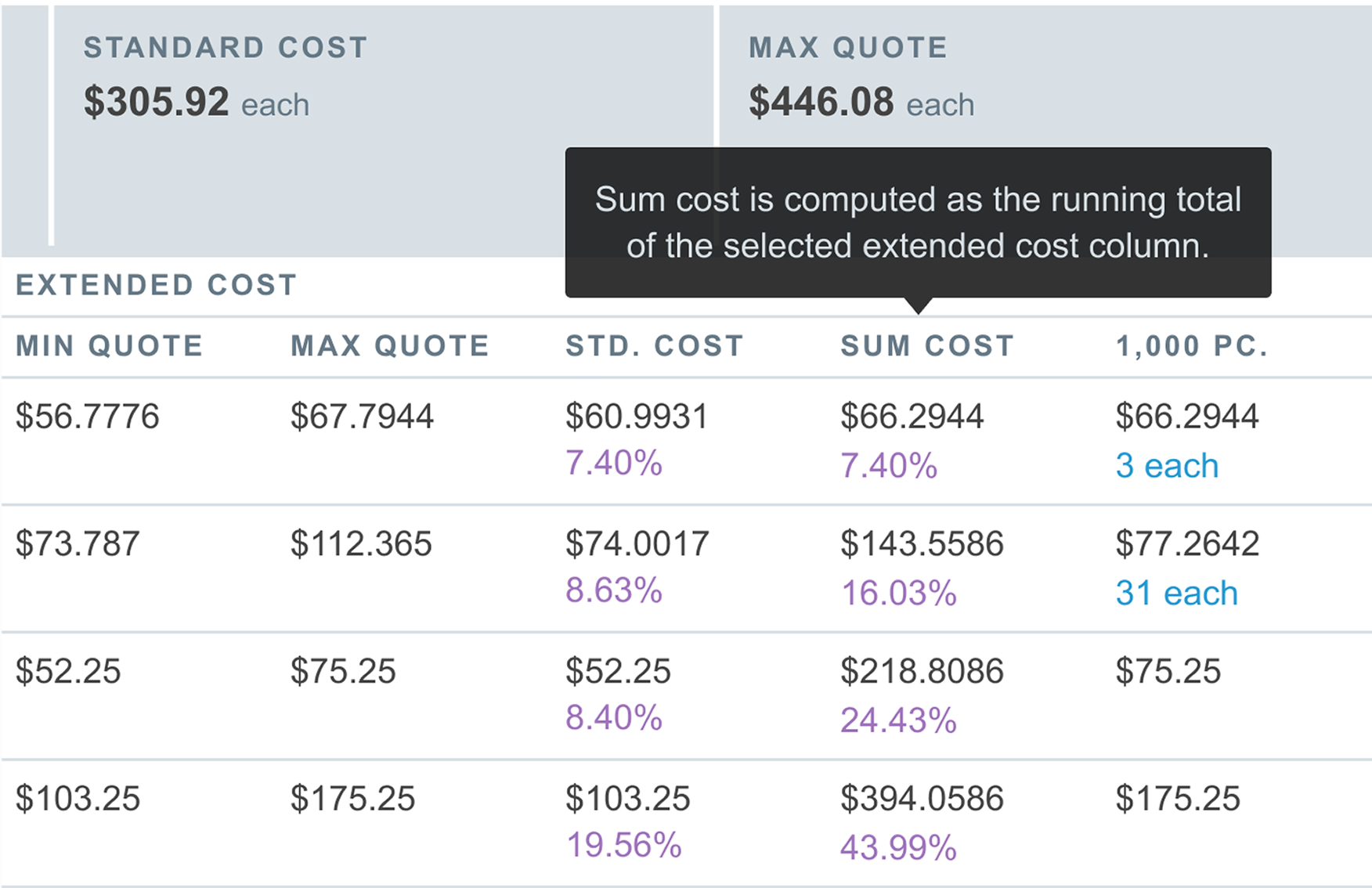

Accurate Product & Build Costing

Reduce uncertainty and effort with built-in vendor quoting, support for standard cost, and Aligni’s flexible cost sheet view:

- Instantly calculate project pricing from active quotes and historical purchases

- Automatic volume pricing based on vendor price breaks

- Drill-down computation quickly prices hierarchical BOMs

- Optionally include excess material costs and attrition.

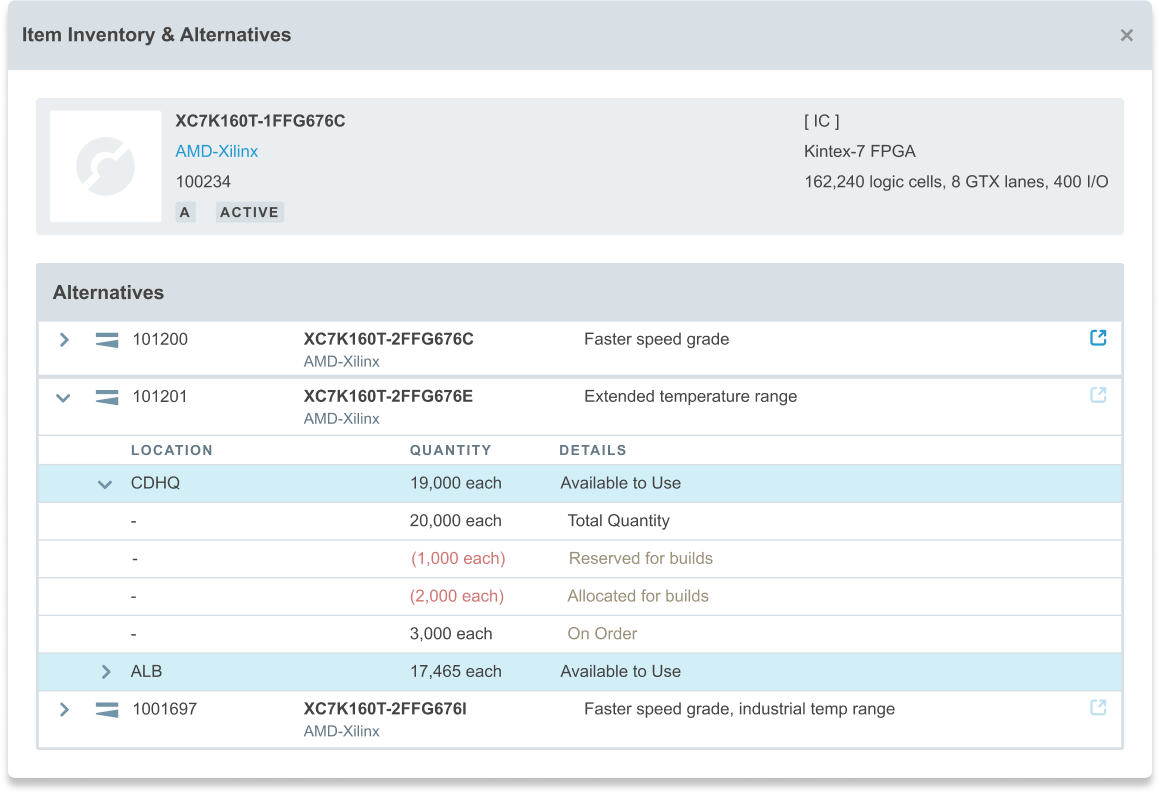

Approved Alternatives

Be more proactive about part availability and lifecycle changes. Engineers can evaluate updates early, and production teams can swap parts on the fly with confidence.

- Approve alternates during design to avoid reactive part changes

- Link substitutes to parent parts for fast visibility at build time

- Keep pricing, lead times, and sourcing details up to date

- Swap with confidence—no BOM edits, no production delays

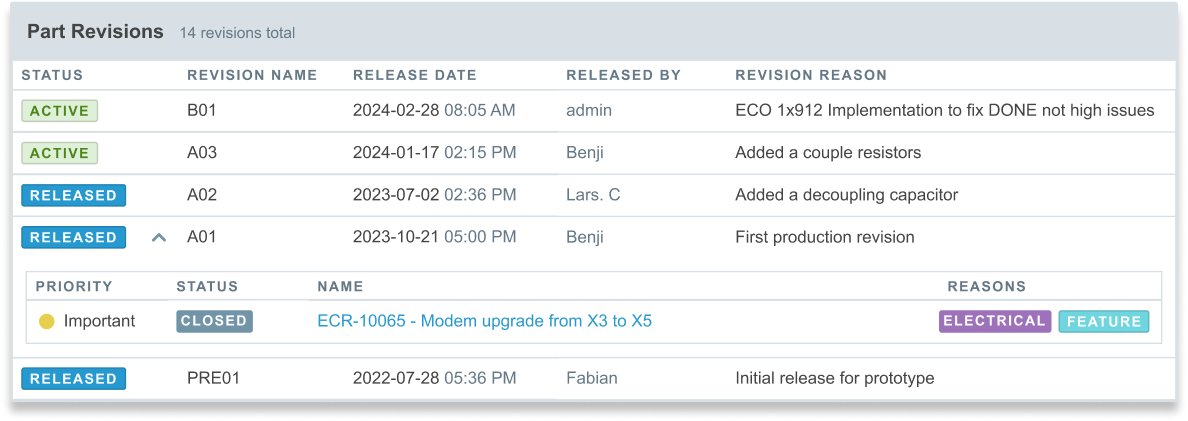

Insightful Revision Navigation

Track every part revision with context. Aligni captures what changed, why it changed, and who changed it—so you never lose sight of the “why.”

- Log revision history directly in the item master

- Tie changes to BOMs, builds, and specs

- Easy access to contributing ECR and ECO

- Preserve institutional knowledge across product lines

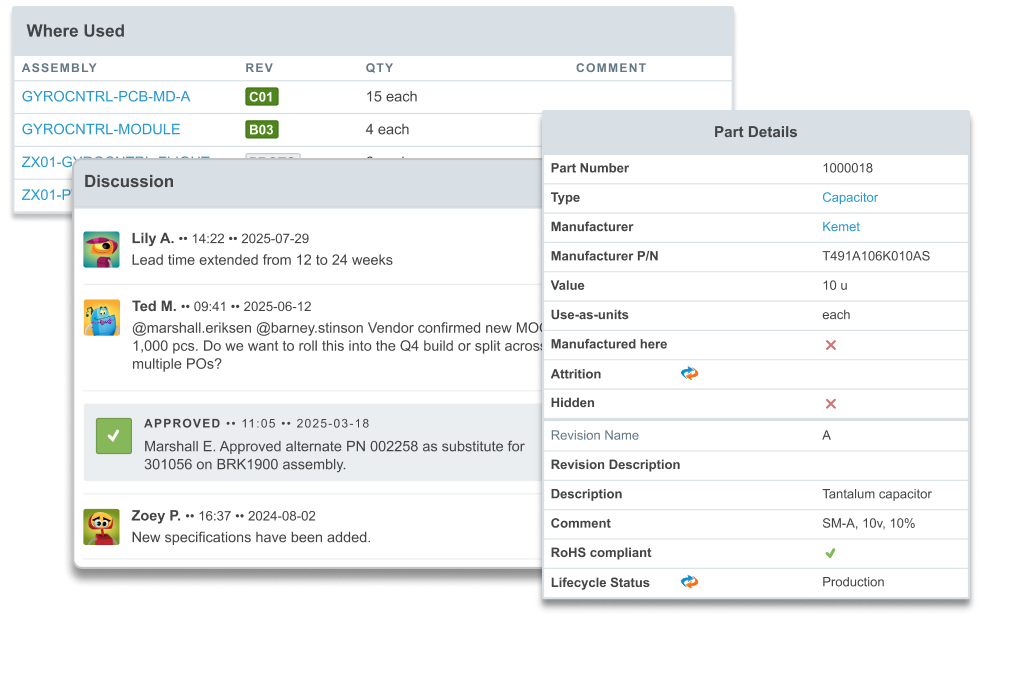

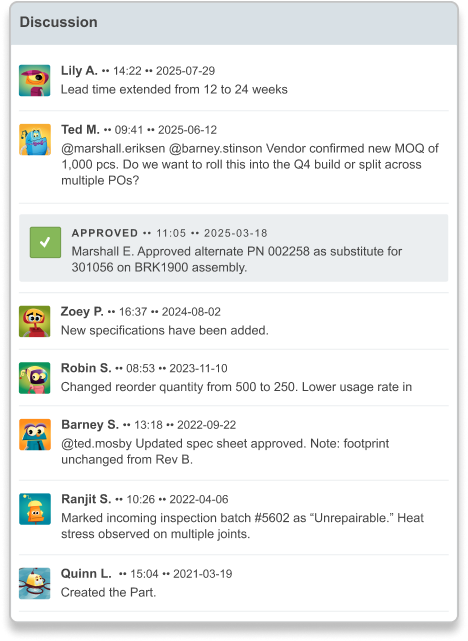

A Living History of Every Part

When you’re managing 10,000 parts—or working with components that are 10+ years old—visibility into the past matters. Aligni keeps a living, searchable record of every change, comment, and quote across the entire lifecycle of a part.

- Review past discussions and approvals on sourcing, cost, and lifecycle status

- Understand historical availability, vendor quotes, and alternate part decisions

- Evaluate aging parts and plan transitions before they become urgent

Expedite the Evaluation

Evaluating business software shouldn’t take months. Aligni makes it simple to go from login to live results — no complex setup, no IT support required.

- Test drive a live demo and experience Aligni’s workflows right away. Invite colleagues, load real data, and see how it fits your operations.

- Start a 30-day free trial with free onboarding to get your team moving fast. Importing services are available to help you hit the ground running.