Aligni MRP for Buyer/Planners

The visibility you need to keep production on track.

What is a Buyer/Planner?

At its core, the Buyer/Planner role is about making sure the right parts are available at the right time. That sounds simple, but in small and mid-sized businesses, it rarely is. The role often gets assigned to someone without formal training, like — an office manager, engineer, or owner, — who suddenly has to juggle supplier quotes, purchase orders, and production schedules.

The Challenge

Those who live this role every day know how tough it can be: juggling vendor delays, sudden shortages, and overstock risks while trying to keep production moving. With so much information trapped in spreadsheets and emails, it’s a constant struggle to avoid costly downtime without tying up cash in excess inventory.

Stop chasing parts. Start driving decisions.

Getting Started as a Buyer/Planner

If you’re new to buying and planning — or just need a clear place to begin…

Start with Visibility into the Basics

Even starting small with these steps gives you immediate visibility and confidence. From there, Aligni grows with you, helping you move from firefighting shortages to proactively planning your supply chain.

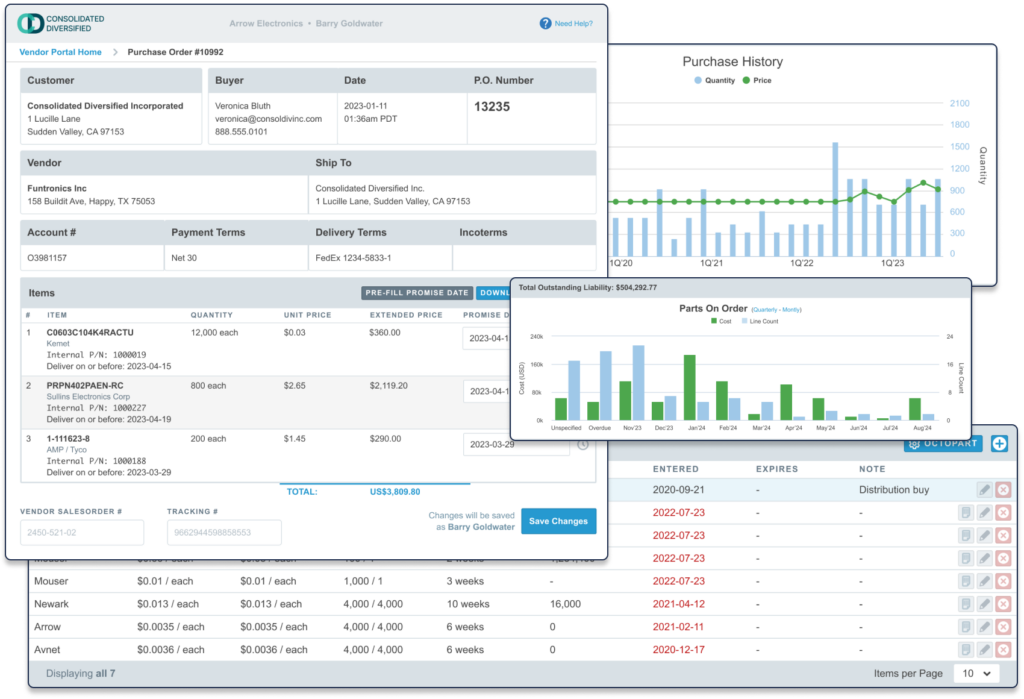

- Quotes and Orders – Centralize RFQs, POs, and vendor updates in one place, improving accessibility and cutting the time wasted digging through emails.

- Inventory Levels – Know exactly what’s on hand, what’s already committed to builds, and what’s arriving soon.

- Part Information – Access specs, revisions, and approved alternates without hunting through spreadsheets.

- Vendor Records – Keep terms, past pricing, and performance history at your fingertips for smarter negotiations.

Aligni MRP acts as a buyer/planner’s command center — showing what to buy, when to buy it, and how to align it with production needs. It removes the guesswork and spreadsheet juggling, giving buyer/planners confidence that materials will be ready when needed.

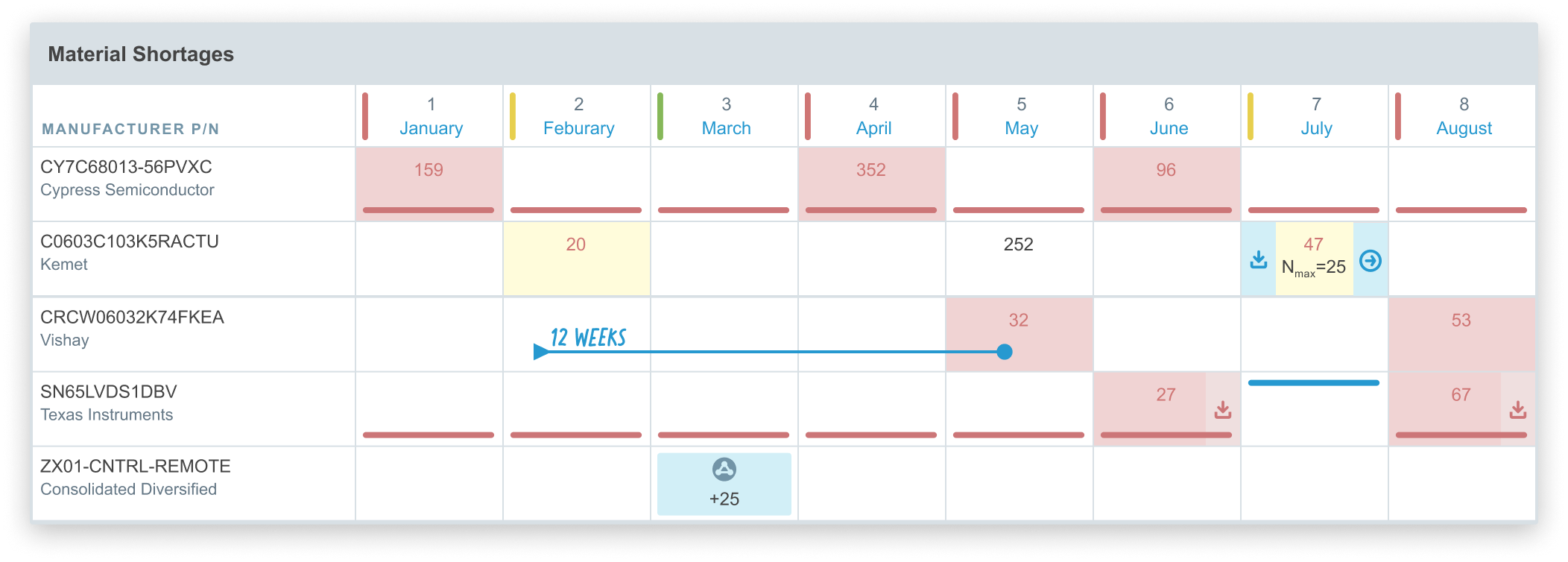

Review Demand Against Inventory

Instead of piecing together demand from scattered spreadsheets, buyer/planners get one clear view of what’s needed. Aligni pulls sales orders, forecasts, and BOMs into a centralized dashboard that translates them into precise material requirements.

- Material Shortage Report (MSR) — Pinpoints exactly which components are needed, when, and where risks exist.

- Time-phased demand clarity — Shows part needs across every order to help you plan ahead with confidence.

- From reactive to strategic — Anticipate shortages instead of scrambling to fix them at the last minute.

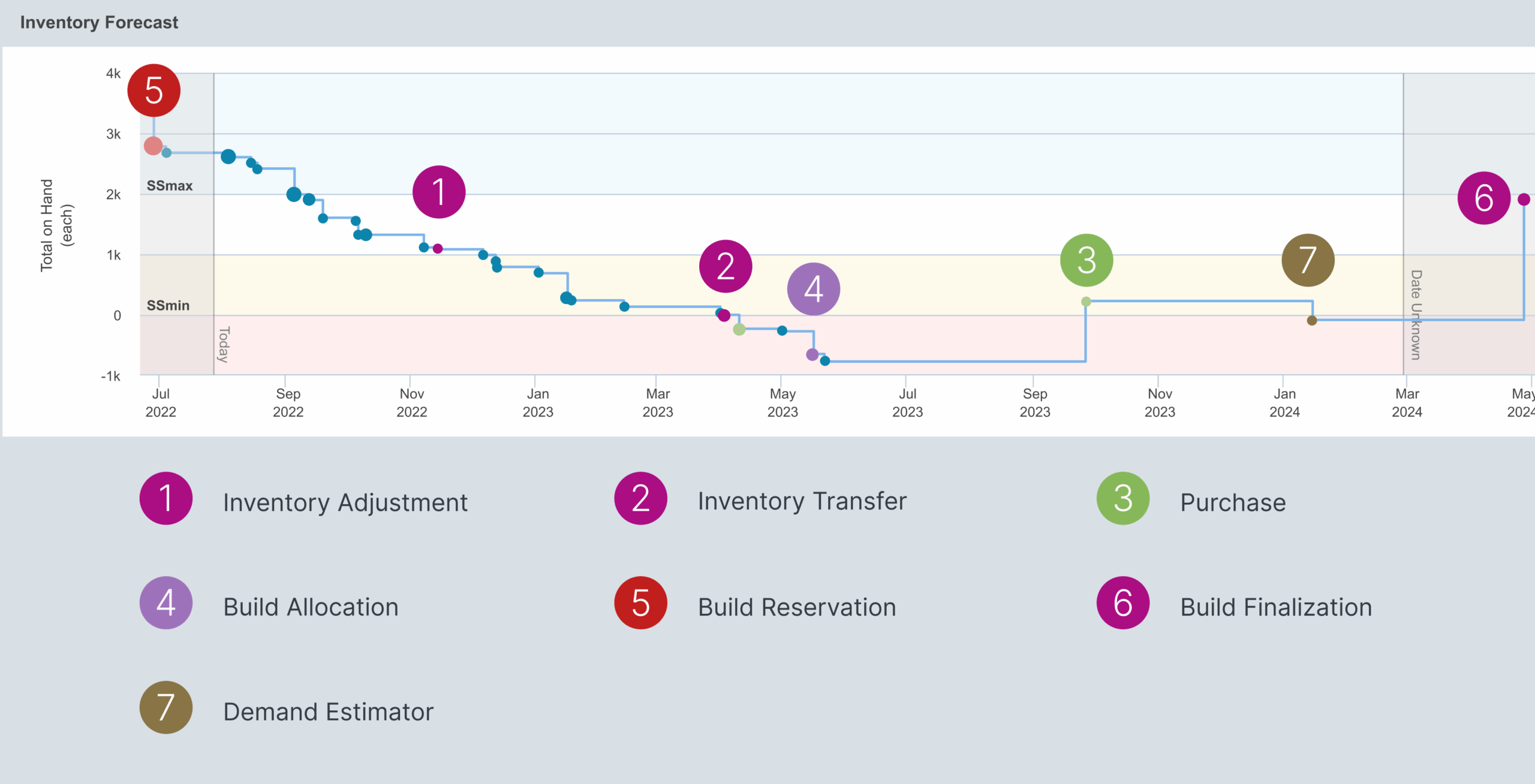

Manage On-hand and Incoming Materials

Managing inventory is about more than counting parts. With Aligni, current stock, open purchase orders, and allocations are visible in one real-time view, so you always know what’s available and what’s on the way. Safety stock levels, lead times, and order deadlines can be set and monitored directly in the system.

- Clear visibility across stock and orders — Always know what’s available, what’s committed, and what’s arriving soon.

- Safety stock safeguards — Prevent shortages while still keeping lean inventory levels.

- Confidence to negotiate better terms — Consolidate buys with long-range visibility to reduce costs.

- Accurate delivery dates mean fewer surprises and smoother builds.

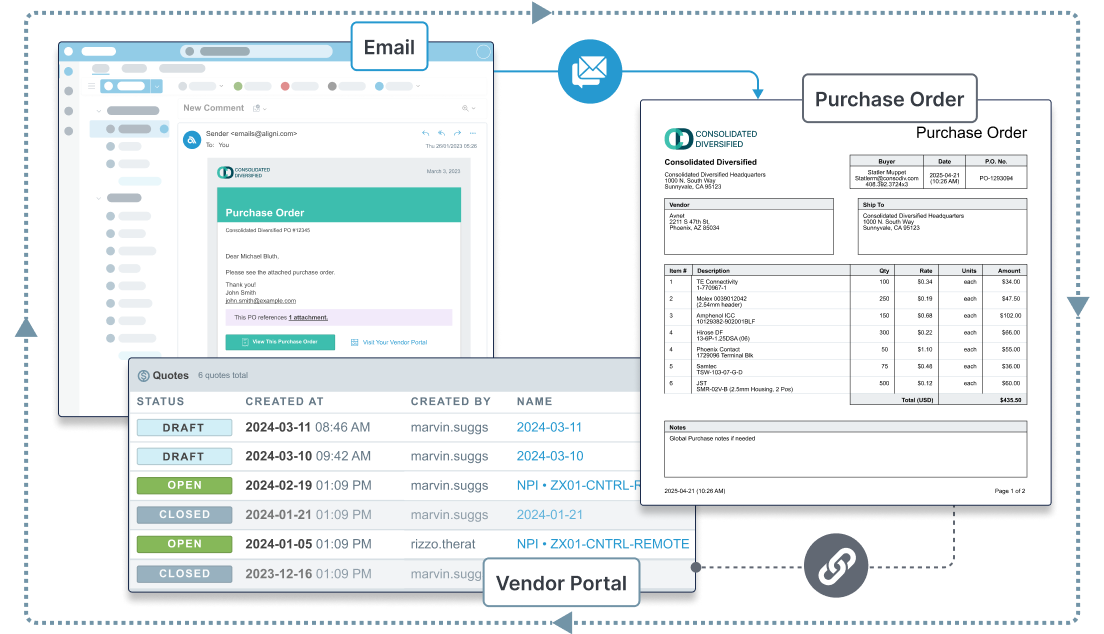

Originate and Track RFQs and POs from One System

Procurement doesn’t have to be complicated or disconnected from the rest of the company. Aligni streamlines the entire cycle so every request, order, and acknowledgment is tracked in one system:

- Send RFQs directly to vendors from within Aligni, keeping vendor outreach in place

- Convert planned orders to POs instantly and push them to suppliers with a click.

- Track acknowledgments and delivery updates automatically, so everyone in the organization is in the loop and delays are flagged early.

This end-to-end workflow reduces errors, strengthens supplier communication, and ensures orders always support production schedules.

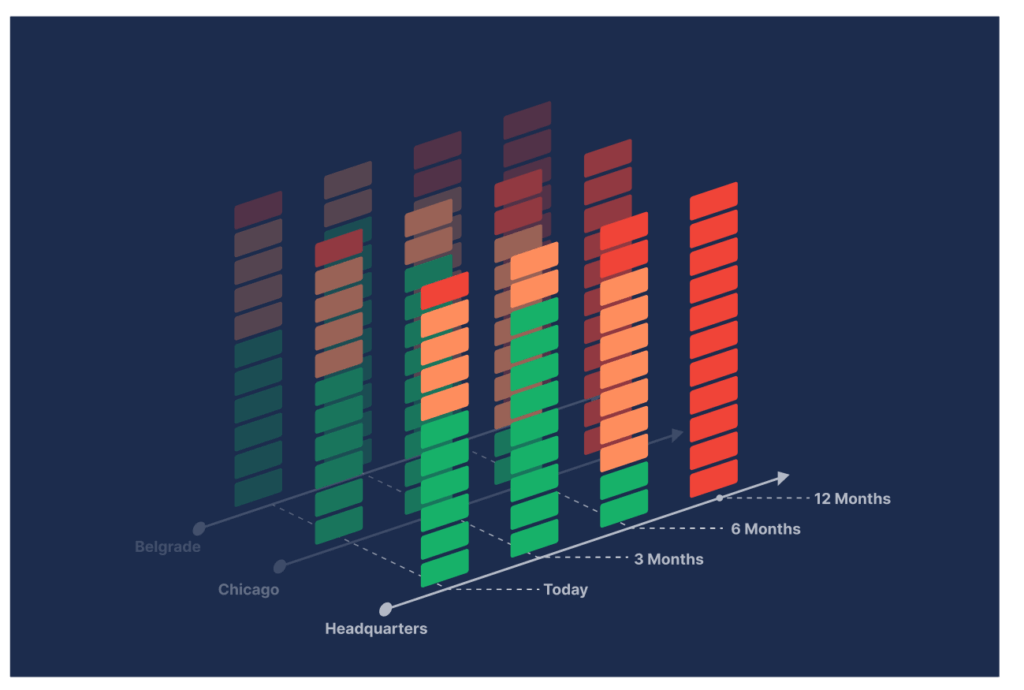

Test Scenarios Before Making Changes

Schedules shift. Builds get added. Supplier dates slip. Aligni keeps buyer/planners prepared by recalculating material requirements the moment conditions change.

With TimeWarpTM, you can run “what-if” scenarios to see how changes affect inventory and production before committing. Instead of reacting to disruptions, buyer/planners can fine-tune orders, push dates, or expedite shipments with confidence — keeping production moving without unnecessary cost.

Supporting Continual Improvement

Purchasing isn’t just about placing today’s order — it’s about making smarter decisions tomorrow. Aligni automatically tracks historical orders, pricing trends, and approved alternates, all in one place.

- Historical data for smarter buying — Compare costs, trends, and past negotiations with ease.

- Flexibility with approved alternates — Keep production moving even if your first-choice supplier slips with pre-approved replacement parts and backup vendors.

- Continuous improvement built in — Use data and insights to buy better and plan smarter over time.

Buyer/Planner Role Frequently Asked Questions

Expedite the Evaluation

Evaluating business software shouldn’t take months. Aligni makes it simple to go from login to live results — no complex setup, no IT support required.

- Test drive a live demo and experience Aligni’s workflows right away. Invite colleagues, load real data, and see how it fits your operations.

- Start a 30-day free trial with free onboarding to get your team moving fast. Importing services are available to help you hit the ground running.