Managing Quality Control in Aligni

Whether you’re upgrading from outdated methods or starting fresh, Aligni gives you a clear path forward.

The Challenge: Quality That Slips Through the Cracks

For many small and mid-sized manufacturers, quality control is harder than it should be. Inspections are logged in spreadsheets, supplier defects get buried in email threads, and test results are often disconnected from the rest of production data. Without a consistent process, issues slip downstream causing rework, missed deadlines, or even failed certifications.

The Solution: Build Quality Into Every Step

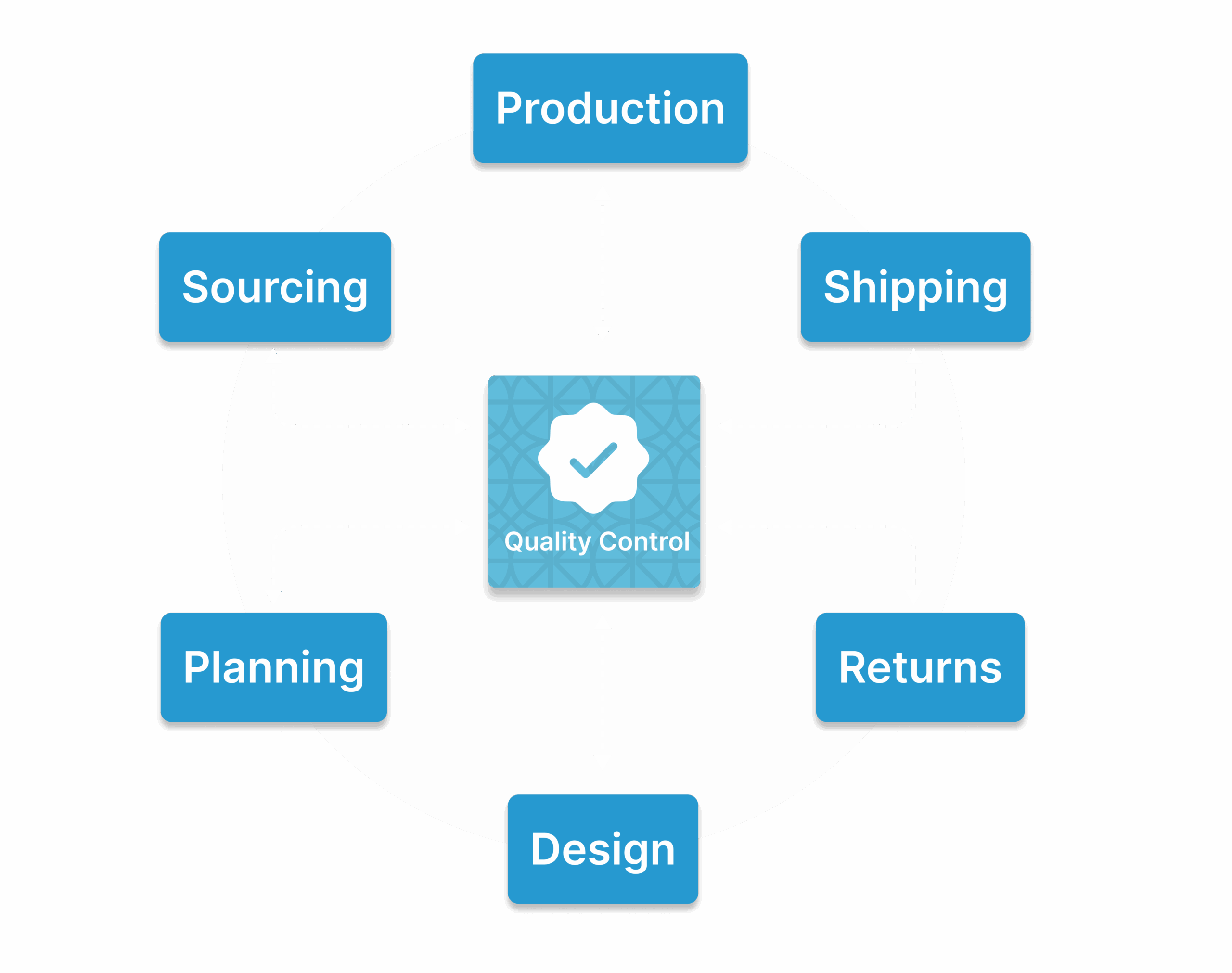

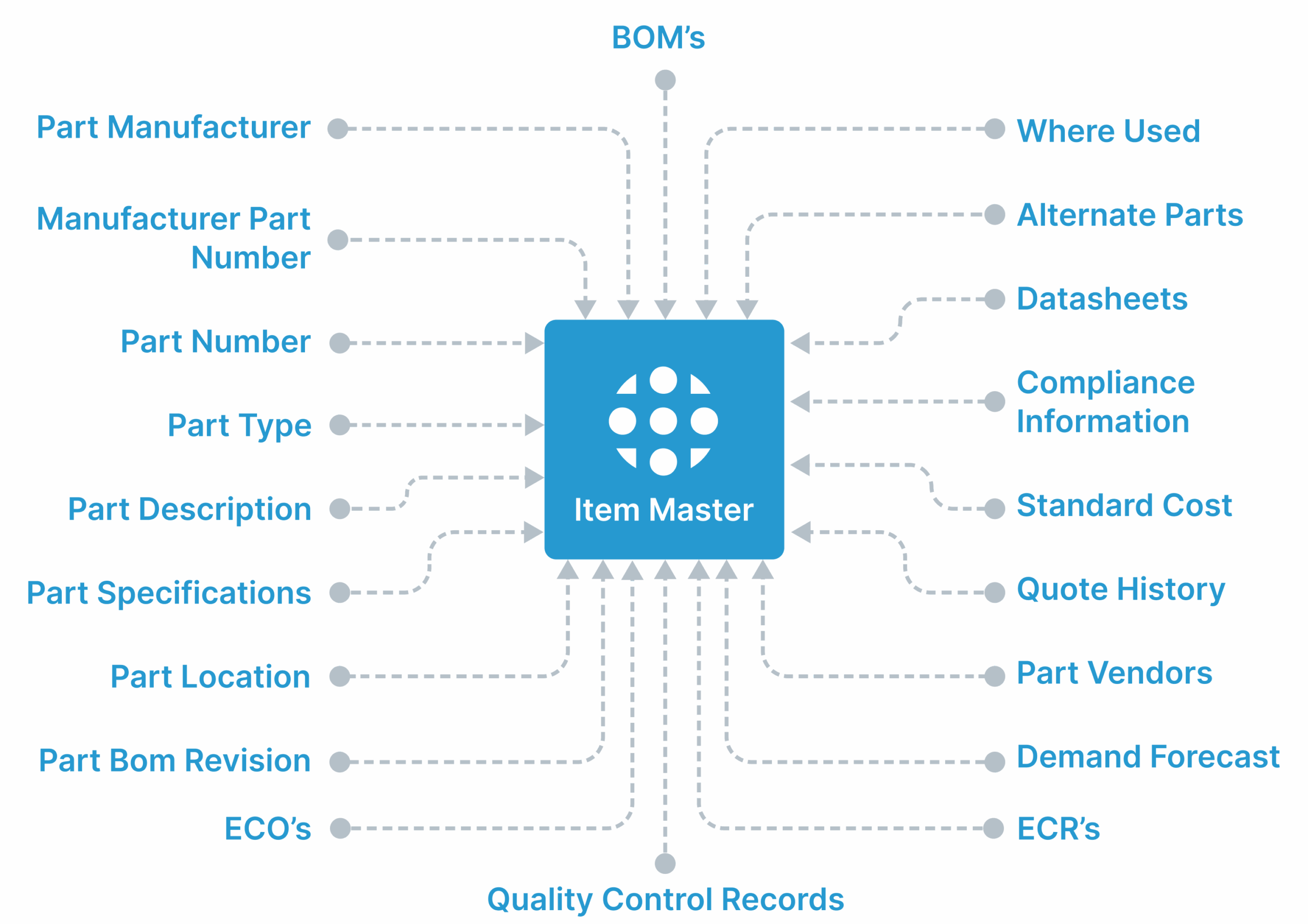

Aligni MRP integrates quality control directly into your production workflows. Every inspection, test, and non-conformance report lives alongside your BOMs, builds, and supplier records. That means quality data isn’t siloed—it’s connected, visible, and actionable across the entire organization. Instead of treating QC as an afterthought, Aligni makes it a shared process that improves traceability, compliance, and confidence in every part you build or buy.

Where to Start with Quality Control

If you’re just beginning to formalize quality control, it doesn’t have to be complicated.

Start by focusing on the basics.

Build a Solid Foundation for Quality

Start with the fundamentals. Aligni Quality Control builds on the same principles and helps you evolve past manual and disconnected workflows.

Standardize Quality from the Start

For many small manufacturers, quality control is an afterthought. Test results live in spreadsheets, inspection data sits in emails, and supplier defects go untracked until it’s too late. Without a consistent system, it’s easy for problems to slip downstream, causing rework, missed deadlines, or even failed certifications.

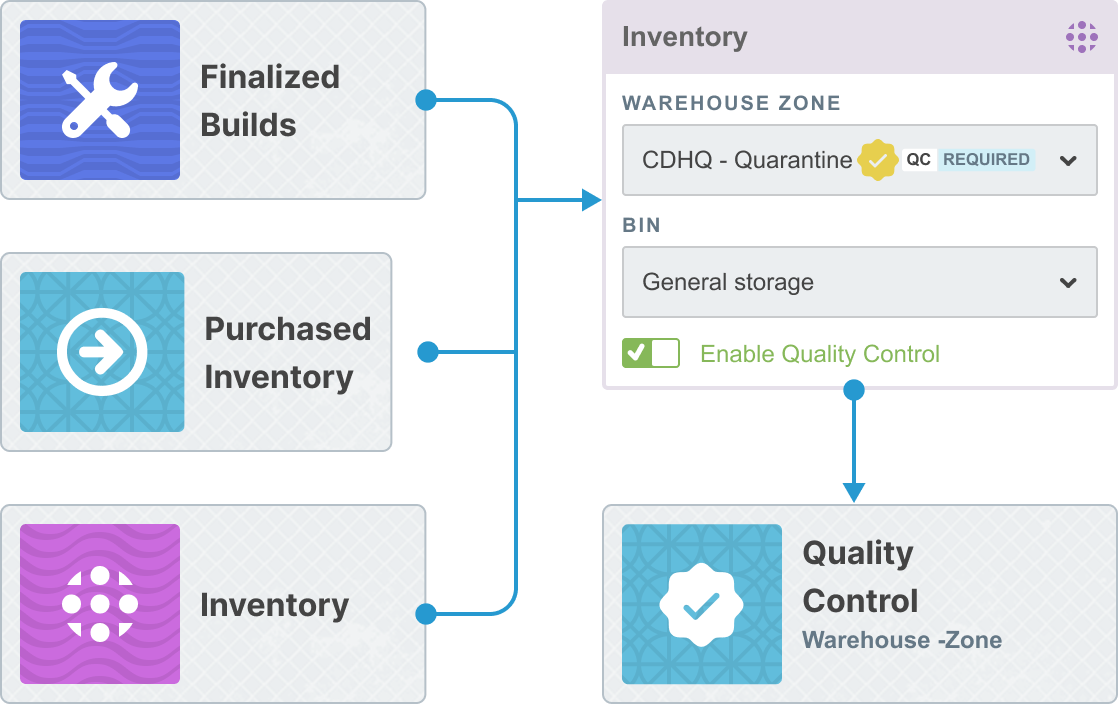

Aligni MRP comes with a complete, integrated quality control (QC) system that makes managing product quality simple, consistent, and transparent across your organization. Because QC is built directly into Aligni, the entire process—and its test data—is available to every department, not locked away in a separate system.

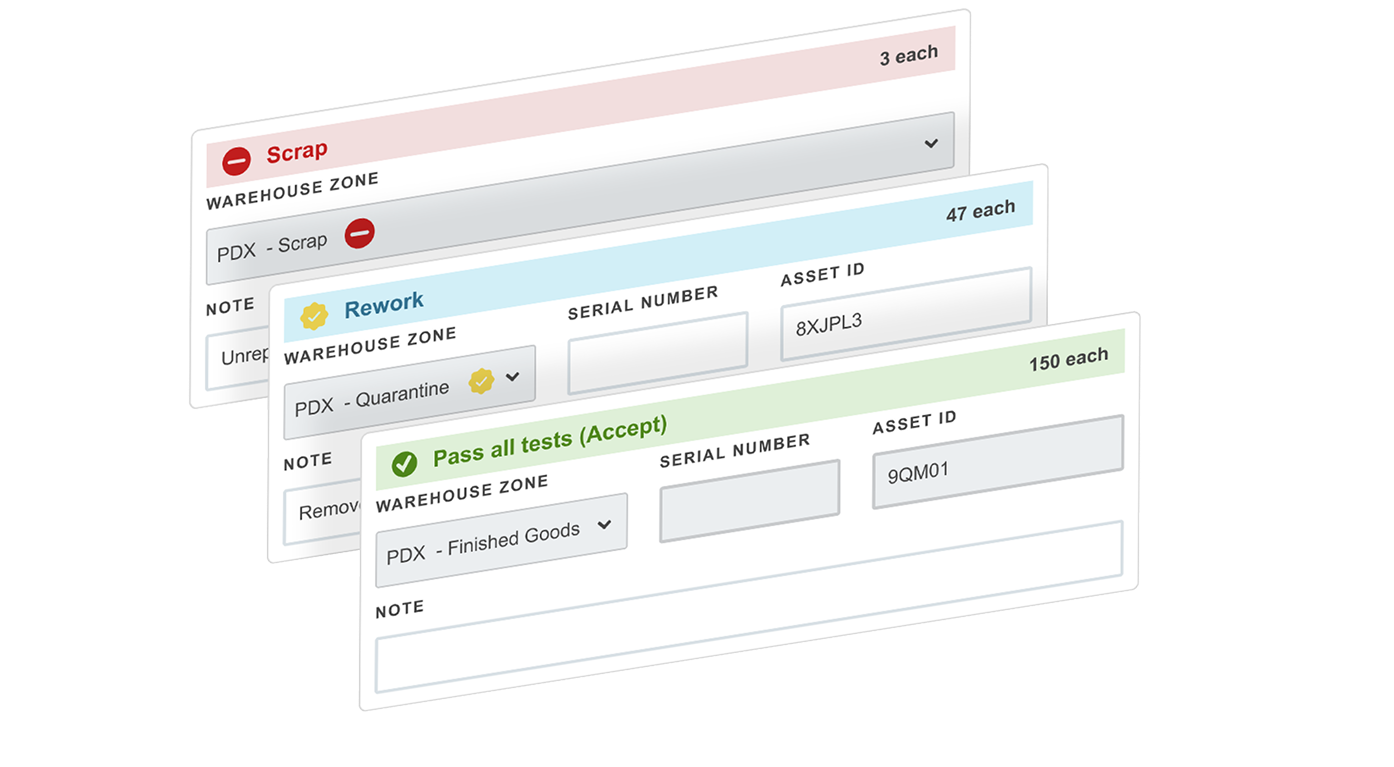

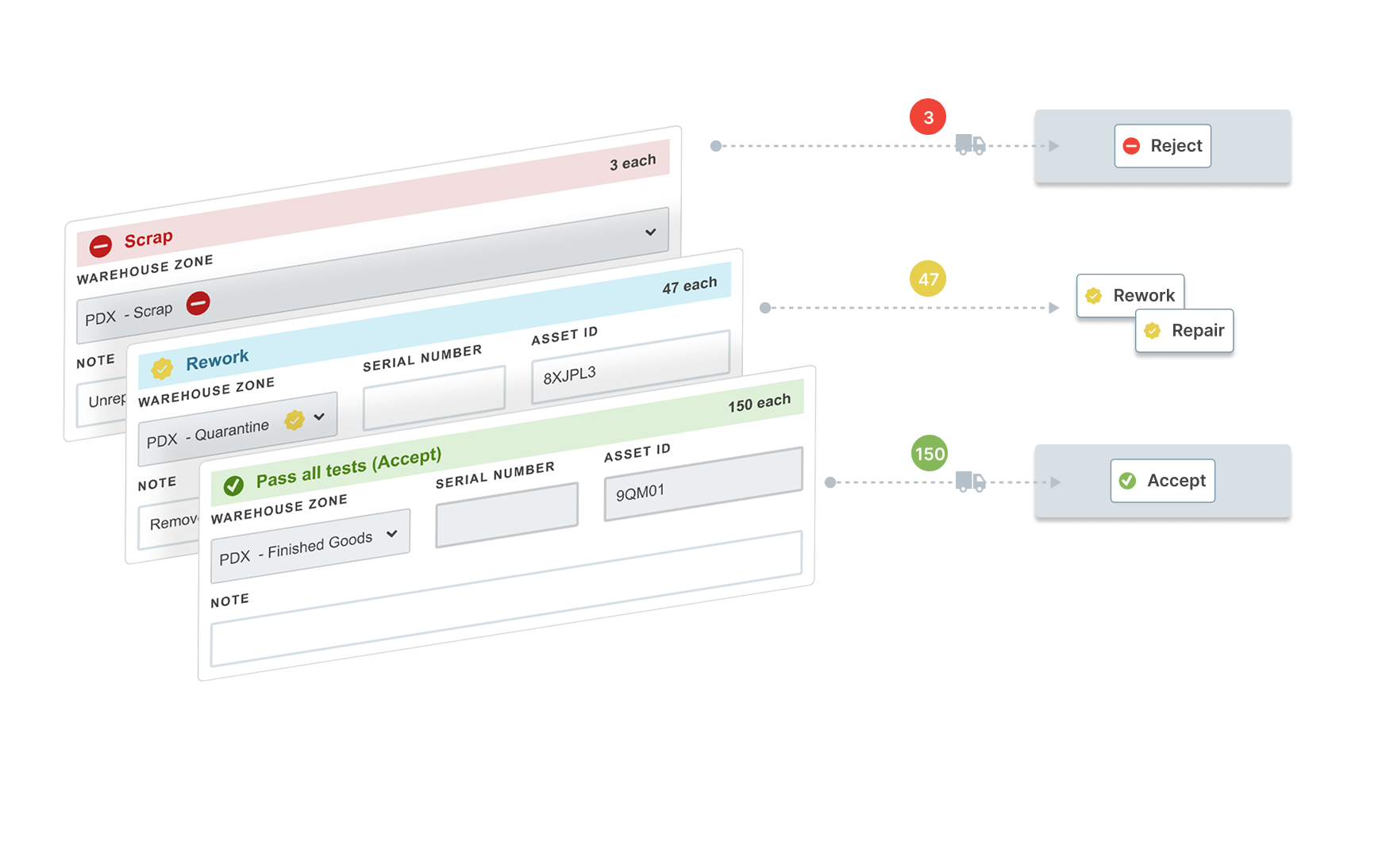

Document Outcomes, Build Confidence

Using Aligni’s quality control process makes every inspection a standardized, repeatable process. Test results become living records stored in the item master, with pass, rework, and fail outcomes captured the same way every time.

When Aligni’s QC functionality is utilized, it delivers big advantages for SMBs:

- Consistency: Every batch is inspected the same way, making results easy to compare over time.

- Efficiency: New staff get up to speed quickly by following one clear process.

- Traceability: Records are always linked to the item master for complete visibility.

- Compliance: Demonstrates process reliability to support certifications like ISO 9001.

See Supplier Quality as Clearly as Product Quality

Aligni tracks the quality of purchased parts right alongside the parts you build. Supplier performance, defect rates, and non-conformance incidents are logged in the same system as production test data, giving you a complete picture of reliability. Purchasing teams can spot long-term trends and make sourcing decisions that strengthen partnerships and reduce production risks.

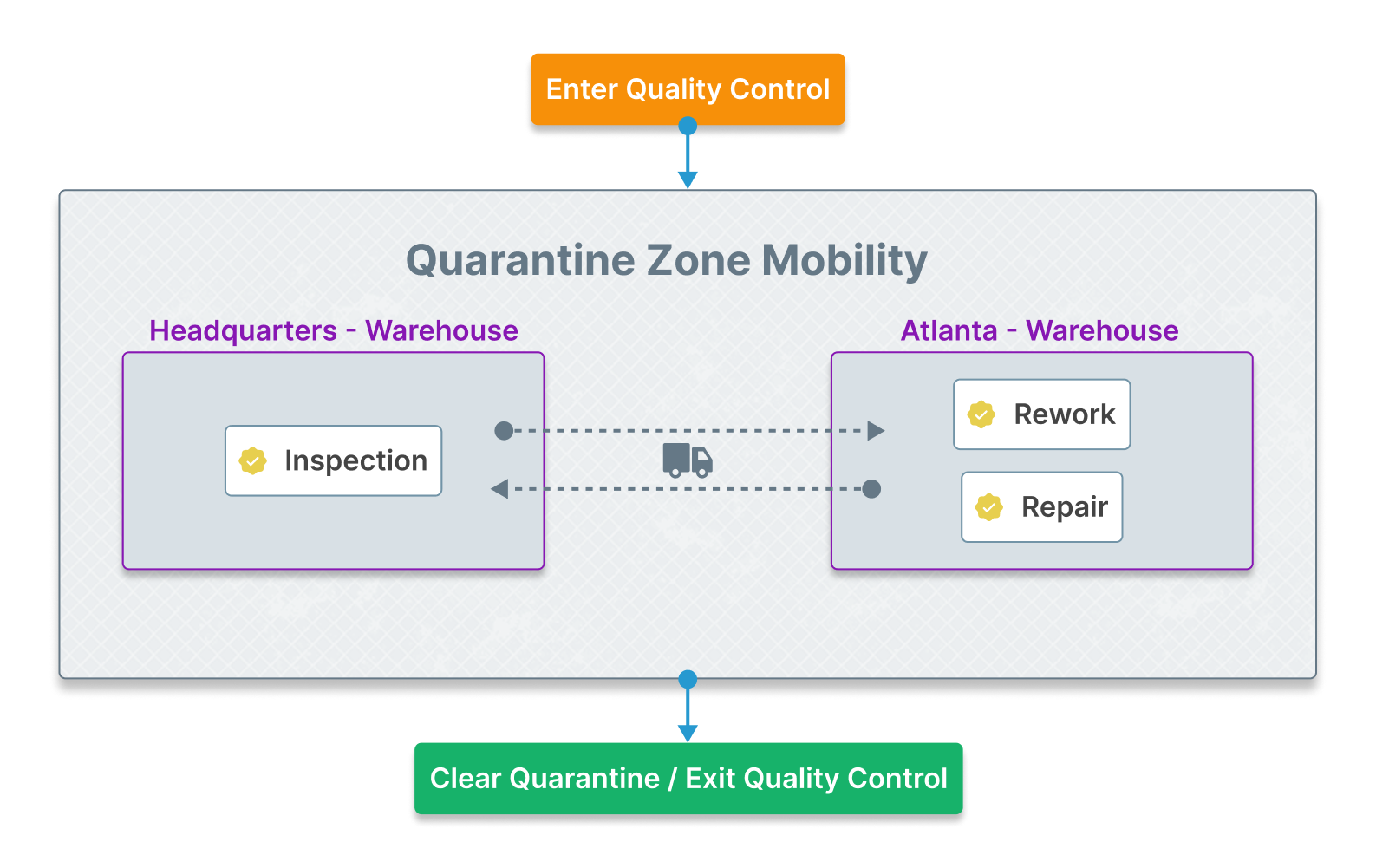

Separate “Passed” from “Unproven”

When the QC process is used, Aligni automatically separates untested items from usable inventory. Parts remain in QC locations within the Aligni database until testing is complete, preventing premature allocation. Approved parts flow into stock, rejects move to scrap or RMA, and production always works from accurate counts. This segregation eliminates double-counting, prevents stockouts, and keeps builds on track.

Tie Inspections to Production Steps

Inspections can be built directly into production steps — from in-process checks to final tests. Work orders can’t move forward until each checkpoint is cleared, preventing defects from slipping downstream. Results are stored in Aligni for trend analysis, customer reporting, and process improvement, ensuring quality is enforced at every stage.

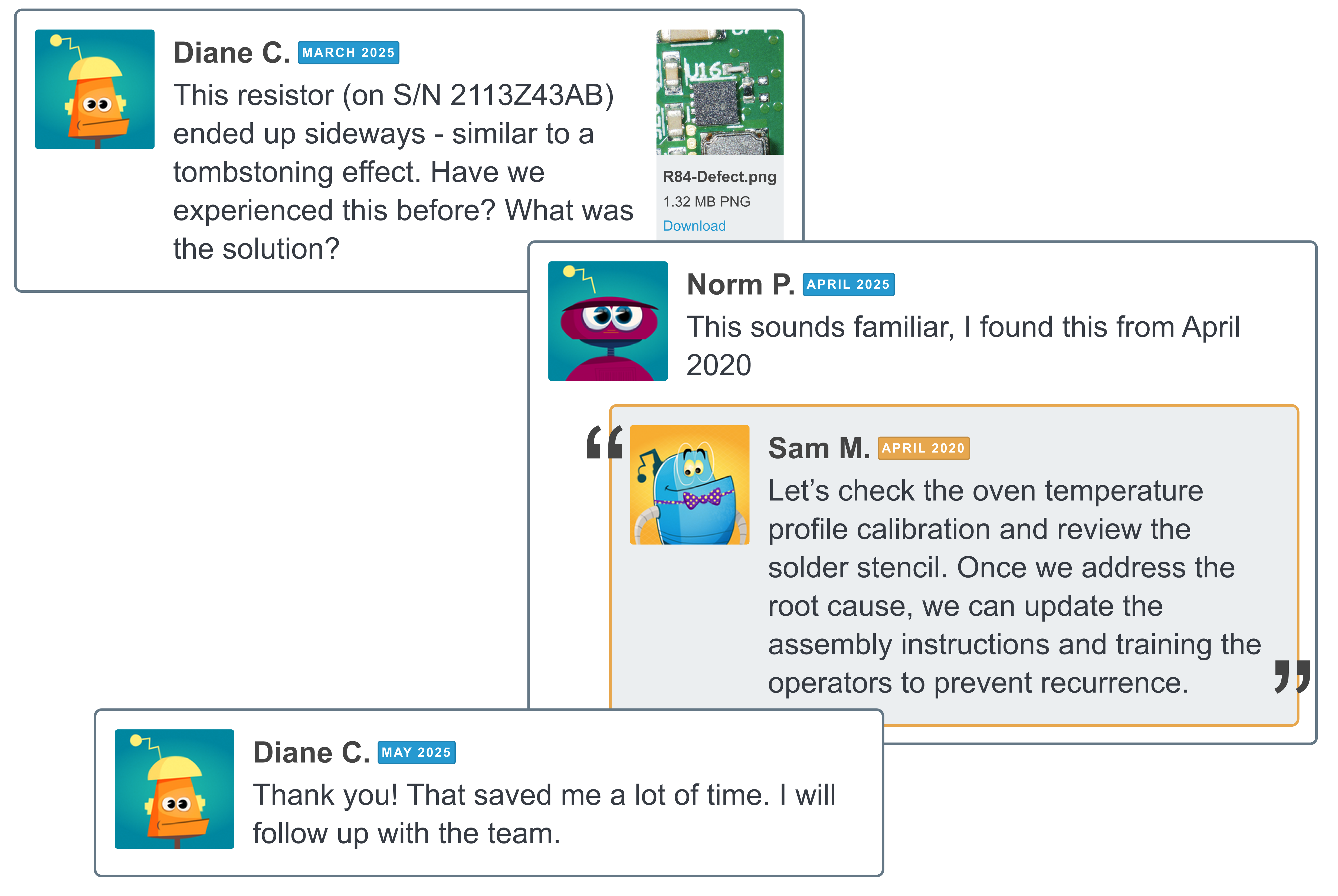

Close the Loop with Non-Conformance Management

Non-conformance reports are logged and linked to the affected batch, supplier, or operator. Teams can document corrective and preventive actions, then issue ECOs to push changes across the system. This ensures fixes are implemented, tracked, and verified — turning quality issues into opportunities for continuous improvement.

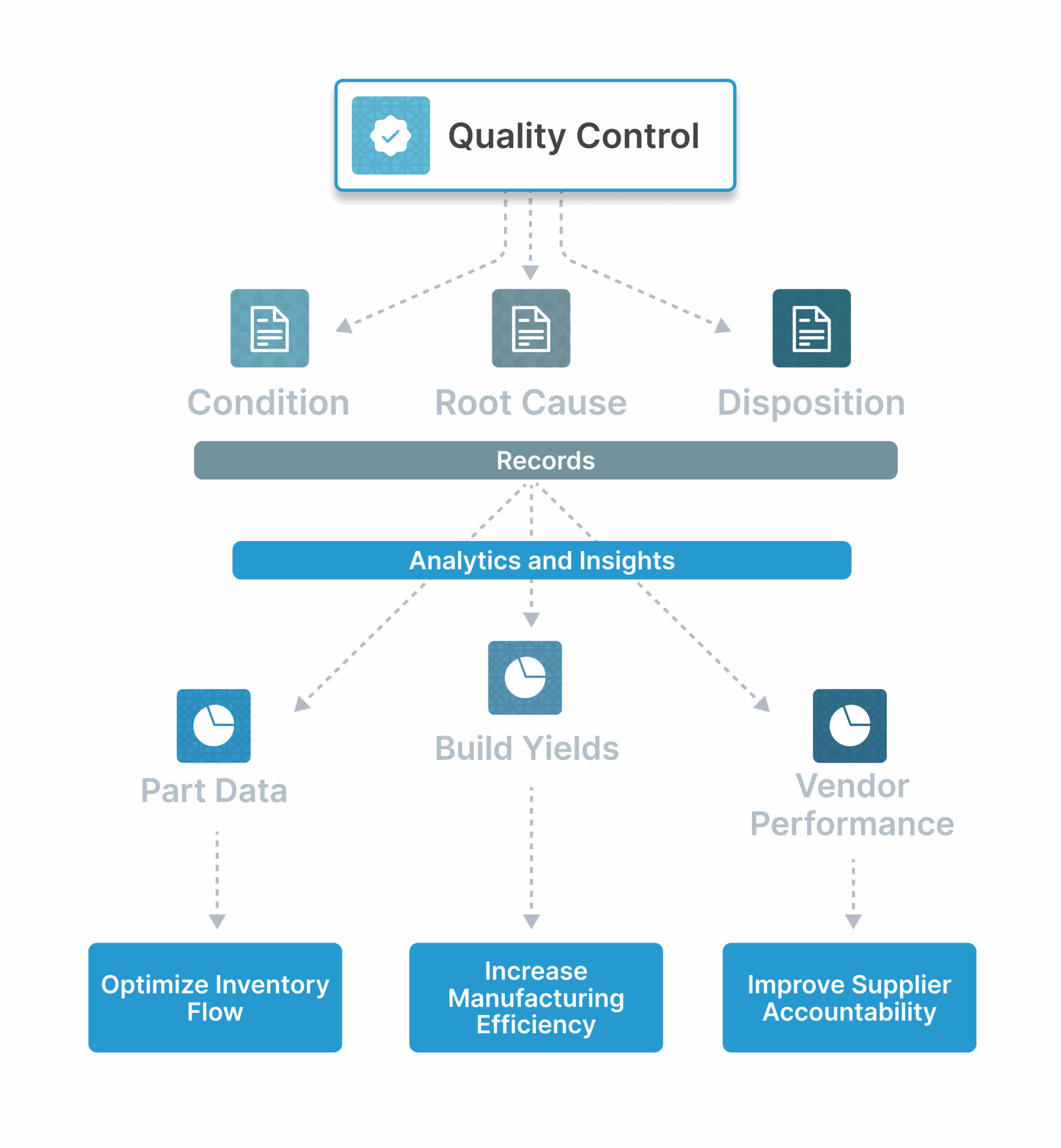

Turn Quality Data into Actionable Insights

Connected Data Delivers Clarity

Aligni MRP doesn’t just capture inspection results — it connects them to BOMs, work orders, and supplier history. This gives manufacturers a clear view of defect trends, root causes, and the true cost of quality.

- Spot trends faster by linking results across builds and suppliers

- Trace root causes with data tied directly to every part and process

- Automate audit trails to save time and reduce manual effort

Because everything lives in one database, defects can be traced back to suppliers, builds, or production stages. This connected view helps teams catch issues earlier, resolve them faster, and build a culture of continual improvement.

Collaborative Quality Across the Organization

Because QC lives in the same system as purchasing and production, every department benefits. Buyers see supplier quality history when placing orders. Production teams factor in fail rates when planning builds. With shared visibility, the whole organization can respond quickly and work together to raise quality standards.

Integrating Quality Frequently Asked Questions

Expedite the Evaluation

Evaluating business software shouldn’t take months. Aligni makes it simple to go from login to live results — no complex setup, no IT support required.

- Test drive a live demo and experience Aligni’s workflows right away. Invite colleagues, load real data, and see how it fits your operations.

- Start a 30-day free trial with free onboarding to get your team moving fast. Importing services are available to help you hit the ground running.