For small and medium sized businesses, most Enterprise Resource Planning (ERP) systems are just too expansive for their purposes, but that doesn’t mean companies cannot learn best practices on their path to adopting more right-sized business software.

On ReadWrite, Claus Jepsen has posted an article about things to look out for when implementing an ERP system. While smaller manufacturers may not need everything that comes with ERP, these tips also translate to migrating to a system that’s much more suited to their needs, like a Materials Requirements Planning (MRP) system.

Perhaps the most important aspect of all the tips in the article revolves around making sure the organization as a whole is ready to use the system – not the mechanics of making the software work. There’s a lot of work that needs to be done to get the company itself ready for the software before getting the software ready for the company. Processes have to be outlined and buy-in has to be achieved with different groups within the organization before the software can be implemented. Regardless, if you’re implementing an ERP, MRP or PLM system, these tips are relevant for successfully adopting any software system.

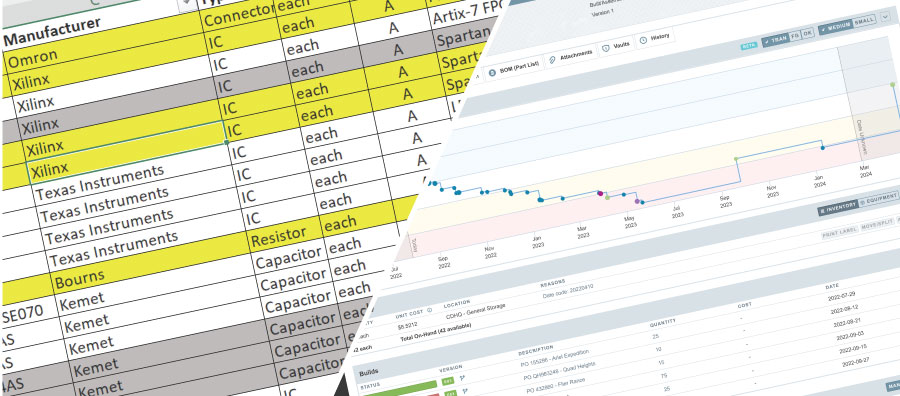

If you’re looking for a better way to manage your manufacturing and inventory management, we suggest you learn more about Aligni MRP. To help reduce the uncertainty of the process, we’ve also put together some information on what it takes to implement an MRP system.