In the fast-moving world of electronics manufacturing, keeping production efficient isn’t just about machines and materials—it’s also about how effectively people communicate. Traditional methods like email threads, meetings, and scattered notes often slow things down, especially when teams are working across shifts, time zones, or departments.

Aligni’s built-in collaboration feature, DiscussAnything, introduces a new, more efficient way to have critical conversations. Instead of waiting for schedules to align or digging through inboxes, teams can hold discussions right where the work happens—linked directly to parts, BOMs, and production processes. This context-driven communication keeps everyone on the same page, accelerates decision-making, and eliminates unnecessary delays.

A Smarter Way to Communicate in Manufacturing

DiscussAnything is designed to help production, inventory and quality managers streamline communication and decision-making within the Aligni MRP system. By linking discussions directly to specific components, assemblies, and workflows, DiscussAnything ensures that conversations remain relevant and accessible where they matter most—within the manufacturing process.

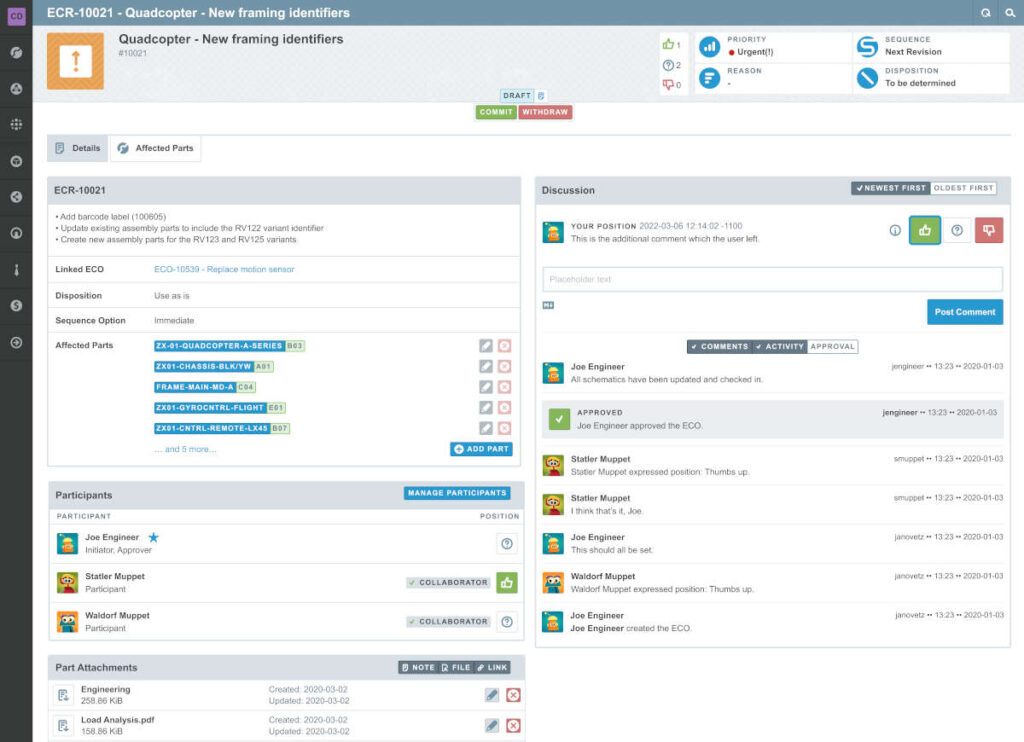

Managers can use DiscussAnything to coordinate inventory updates, address supply chain disruptions, quality control issues, and resolve production issues efficiently. The system allows users to attach key documents, log approvals, and track process changes, creating a centralized record of decisions and actions. This eliminates scattered emails and lost information, providing a structured history of inventory adjustments, BOM changes, and production updates.

More than a messaging tool, DiscussAnything becomes a living record of decision-making across procurement, production, and inventory—capturing why things changed and who was involved.

Work Without Waiting: Keep decisions moving across shifts and time zones

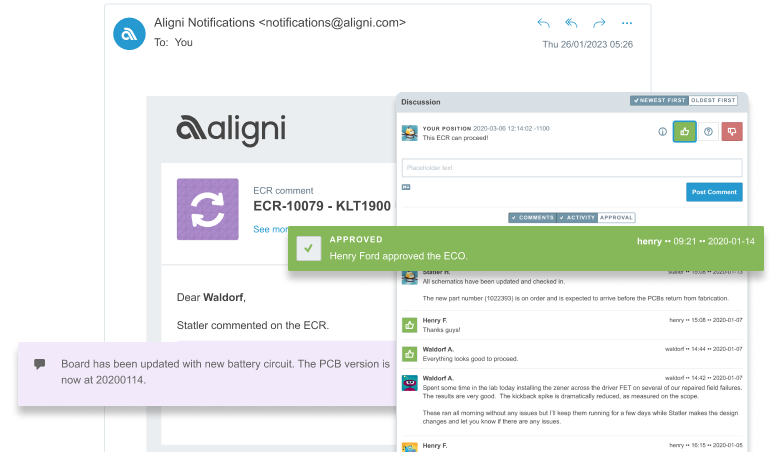

Aligni’s DiscussAnything functionality helps organizations avoid bottlenecks caused by conflicting schedules and keep production and inventory management moving by shifting discussions into a digital workspace. Instead of waiting for everyone’s availability for in-person or video meetings, our collaboration system allows managers and teams to review, contribute, and make decisions at their convenience—regardless of time zone, shift schedules, or geographical location.

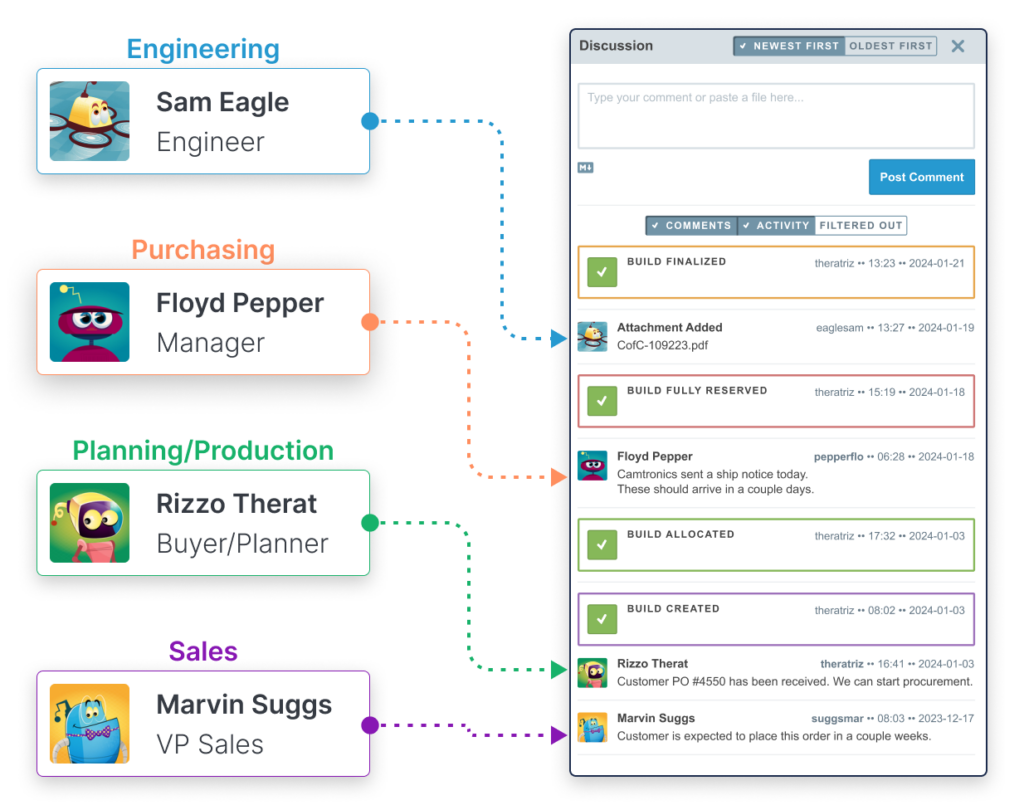

By keeping discussions tied directly to parts, BOMs, quality, and production processes, team members can quickly understand the context and provide input without disrupting workflows. Included notifications ensure that everyone stays informed of updates, approvals, and decisions, keeping conversations active and progress uninterrupted. This approach enables production and inventory teams to stay aligned, resolve issues faster, and keep operations running smoothly—without unnecessary delays from scheduling conflicts, locations or other in-person availability factors.

Enhance Change Awareness Across the Organization

DiscussAnything expands visibility beyond core functional teams, ensuring everyone in the organization stays informed and engaged with critical changes. By accessing the relevant part or process page, any team member can follow ongoing discussions in Aligni MRP, gaining insight into the decision-making process in real time.

Employees outside the immediate change process can subscribe to notifications, staying updated on modifications without being directly involved. Once changes are implemented, the full discussion—including the reasoning behind decisions—is available to all authorized users. This transparency not only ensures that changes are understood but also allows those with valuable insights from other departments to contribute, fostering a more informed and collaborative organization.

Use Past Discussions to Make Smarter Decisions

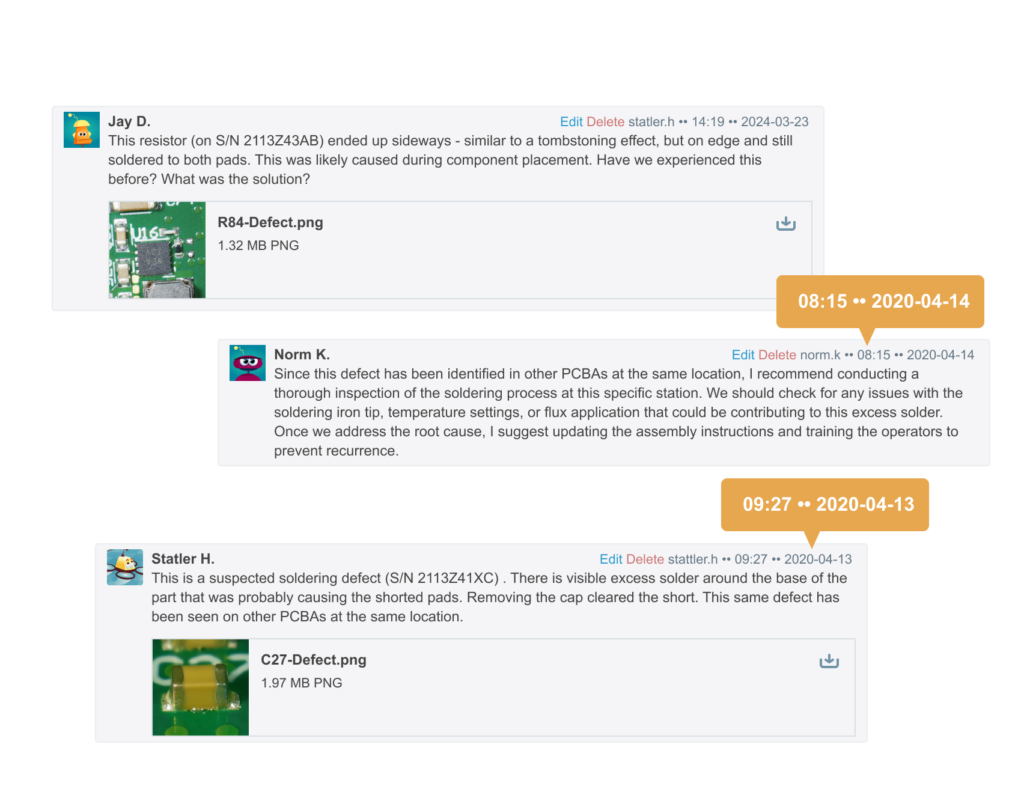

Retaining past DiscussAnything discussions on inventory, quality, and procurement changes creates a valuable knowledge base that helps the organization make informed decisions. By easily locating them within Aligni and reviewing previous Engineering Change Management (ECM) operations, quality issues, and alternative part selections, teams can learn from past resolutions, assess the effectiveness of previous changes, and avoid repeating mistakes.

This historical record preserves critical institutional knowledge that would otherwise be confined to specific departments or lost over time. By making past insights accessible within Aligni MRP, the organization can improve problem-solving, streamline decision-making, and enhance overall operational efficiency.

Examine how decisions are made to streamline processes in the future.

Identify Key Information and Approval Requirements

By reviewing past DiscussAnything threads, organizations can gain a clear understanding of the information and approvals needed to drive changes forward. These records reveal how similar issues were handled, which departments required specific inputs, and who the key decision-makers were in the approval process. This insight helps streamline workflows, ensuring that future changes move through the organization more efficiently.

Pinpoint and Eliminate Process Bottlenecks

DiscussAnything records provides the ability to analyze past issues, allowing teams to trace where delays in the process occurred, identify unnecessary steps, and refine workflows for greater efficiency. By recognizing patterns in decision-making and approval processes, organizations can streamline operations, reduce resolution times, and eliminate redundant tasks—ultimately improving productivity across inventory, quality, and procurement functions.

Taking the Next Step in Organizational Efficiency

DiscussAnything helps manufacturing teams collaborate smarter, resolve issues faster, and reduce operational drag. And it’s just one way Aligni supports efficient, connected production workflows. Aligni MRP also offers a comprehensive suite of features to optimize inventory management, procurement, and production planning, helping your organization reduce waste, improve accuracy, and accelerate time to market.

Discover how Aligni MRP can transform your manufacturing operations today. Visit our website or request a demo to see Aligni MRP in action!