When Small and Mid-sized Businesses (SMBs) begin evaluating software to support their operations, one of the first decisions they face is whether to implement a full Enterprise Resource Planning (ERP) system or a more focused Materials Requirements Planning (MRP) solution.

A key difference between the two is the presence—or absence—of Customer Relationship Management (CRM) functionality. While ERP systems often include CRM modules, MRP systems typically do not. At first glance, this might seem like a limitation. But in reality, the lack of built-in CRM in MRP systems reflects a deliberate and practical design choice. MRP systems are purpose-built to streamline production planning, inventory control, and procurement—not sales or customer engagement.

For SMBs focused on optimizing their manufacturing workflows without the overhead of broader enterprise tools, understanding why MRP systems exclude CRM features can help make a more informed and cost-effective software decision.

Why MRP does not provide CRM functionality

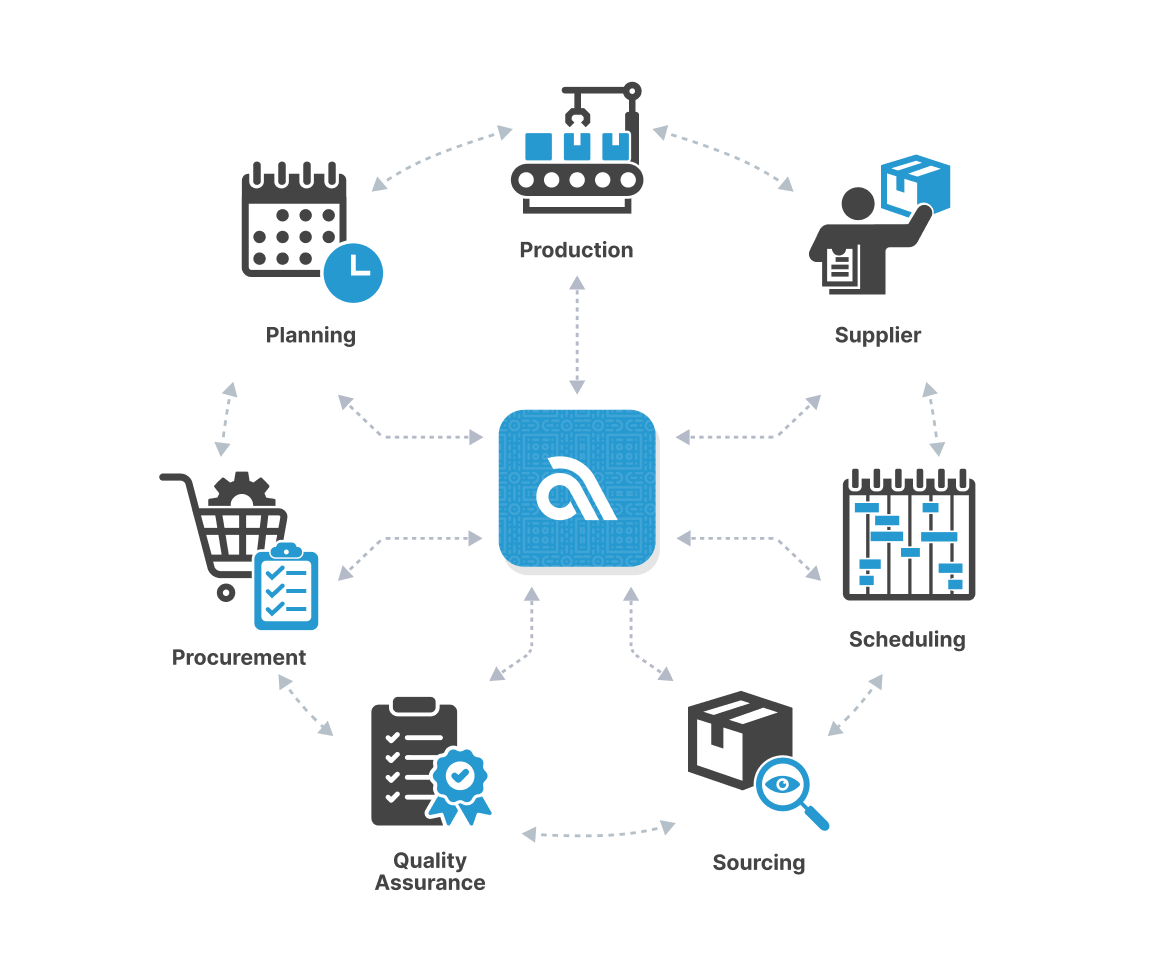

Materials requirements planning systems typically do not include built-in CRM functionality because they are purpose-built for managing production planning, inventory control, and material procurement. These are areas that focus on internal operations rather than customer engagement. MRP systems are designed to answer logistical and operational questions such as what materials are needed, when, and in what quantities. As a result, their workflows are highly structured and transactional, centered on aspects like bills of materials, purchase orders, and work orders. These do not align with the dynamic, relationship-driven nature of customer interactions that CRM systems are built to manage. Additionally, the primary users of MRP systems (production planners, buyers, and operations teams) generally don’t require access to sales pipelines, lead tracking, or marketing tools, so including those features would add unnecessary complexity and cost.

MRP and CRM support fundamentally different processes: CRM manages the customer-facing side of the business, like sales and marketing, while MRP handles fulfillment and resource planning. Attempting to merge these functions into a single system can dilute their effectiveness. For this reason, MRP systems tend to stay focused on operational efficiency, while businesses that need CRM capabilities typically integrate a separate, specialized CRM platform via APIs or middleware. This approach allows each system to excel at its intended purpose while enabling smooth communication between sales and operations.

Why Keeping CRM Separate Actually Helps You

Retaining a separate CRM system from your MRP system, rather than using a single, all-in-one platform, can offer several strategic and operational advantages. This is especially true for small and mid-sized manufacturers looking for flexibility and best-in-class tools. Below are the key benefits of keeping CRM and MRP separate:

1. Best-of-Breed Functionality

CRM systems like Salesforce, HubSpot, or Zoho specialize in sales, marketing, and customer service tools that are often more advanced than those bundled into ERP or MRP platforms. By keeping systems separate, SMBs are provided access to more powerful, modern features, like advanced sales pipelines, customer journey tracking, and marketing automation.

2. Greater Flexibility and Choice

Businesses can choose the best tool for each function, allowing them to match specific business needs instead of being locked into a single vendor’s suite. Easier to swap out or upgrade either system independently as the business evolves.

3. Faster Innovation Cycles

Dedicated CRM platforms often release new features and integrations more frequently than MRP and ERP suites. Separating systems allows companies to take advantage of more rapid innovation on the sales and marketing side without waiting for the slower development pace typical of operational platforms.

4. Easier User Adoption

Sales and customer-facing teams benefit from a purpose-built CRM UI instead of navigating complex MRP or ERP interfaces. This often leads to better user engagement, data quality, and adoption in the CRM.

5. Reduced System Complexity

MRP systems are built for operations and inventory—not customer relationships. Splitting systems allows each to stay focused and optimized for its primary users, minimizing feature bloat or compromise.

6. Improved Data Governance and Control

Keeping customer data and operational data in distinct systems can help with data access control, compliance, and auditing. For example, sales may not need full visibility into BOM structures or supplier lead times, and operations may not need access to prospect records.

7. Lower Upfront Costs

Full ERP suites with CRM add-ons can be costly and overkill for SMBs. You may reduce costs by using a lightweight, standalone CRM alongside a lean MRP system tailored to manufacturing needs.

8. Resilience and Independence

When MRP and CRM systems are distinct, if one system fails or requires maintenance, the other can continue operating independently. This modularity adds a layer of risk mitigation and operational resilience.

9. More Scalable Integrations

With sufficient APIs and middleware in place, integration between separate CRM and MRP systems can be automated and scalable, allowing for real-time order sync, inventory visibility, and customer updates without forcing a full system merger.

Keeping CRM and MRP systems separate empowers you to use each platform for what it does best: driving sales and managing operations, respectively. With smart integration, you can retain the benefits of both worlds: best-in-class tools, adaptability, and strategic flexibility, without sacrificing workflow continuity.

Future-Ready: Why This Pays Off When You Grow

The choice not to integrate CRM functionality directly into an MRP system can offer significant long-term benefits for SMBs planning to adopt a full ERP system as they grow. While it might seem like a drawback early on, keeping CRM separate helps maintain a clean, modular tech stack that’s far easier to scale. When the time comes to implement an ERP, businesses won’t have to untangle or migrate poorly integrated CRM features from the MRP, streamlining the transition and avoiding data conflicts or duplication.

This separation also allows companies to use best-in-class CRM tools during their early stages, rather than relying on basic or rigid CRM functionality baked into an MRP system. As sales and customer management needs become more complex, the business can continue using its established CRM or opt to migrate into the ERP’s native CRM system depending on what aligns best with evolving workflows.

Keeping CRM and MRP systems independent also reduces implementation complexity and costs in the beginning, allowing smaller manufacturers to focus on what matters most—efficient production and inventory management—without overinvesting in systems they don’t yet need. Ultimately, this modular approach gives growing manufacturers more flexibility and control when they’re ready to scale, without having to rework or replace core operational tools.

Take the First Step – Choose the Right MRP

For SMB manufacturers ready to move beyond spreadsheets and take control of their production and inventory processes with a purpose-built, user-friendly system Aligni MRP is the ideal choice. Designed specifically for small to mid-sized teams, Aligni offers powerful MRP functionality without forcing businesses to abandon their existing CRM tools. This allows the sales team to stay aligned by continuing to use the software they already trust. As companies grow, Aligni can scale with them, offering flexible integration into an ERP system when the time is right, ensuring a smooth interconnection without losing valuable operational data or efficiency.

To see how Aligni can modernize your manufacturing management while fitting seamlessly into your existing workflow, visit www.aligni.com and explore your options today.