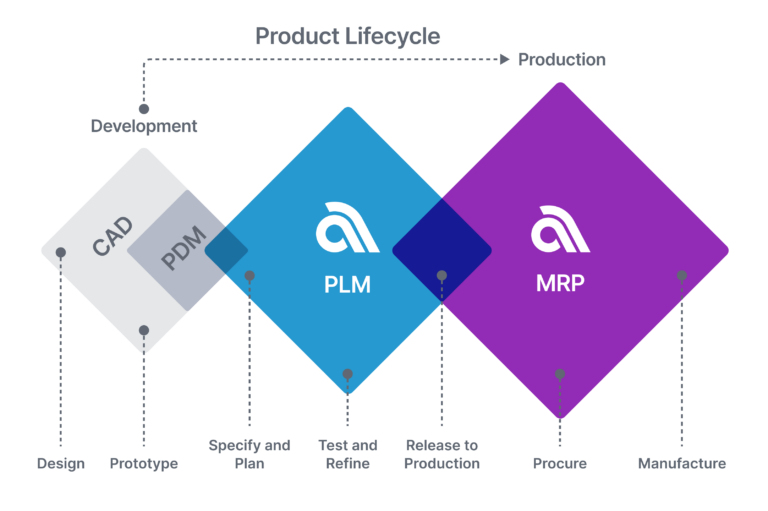

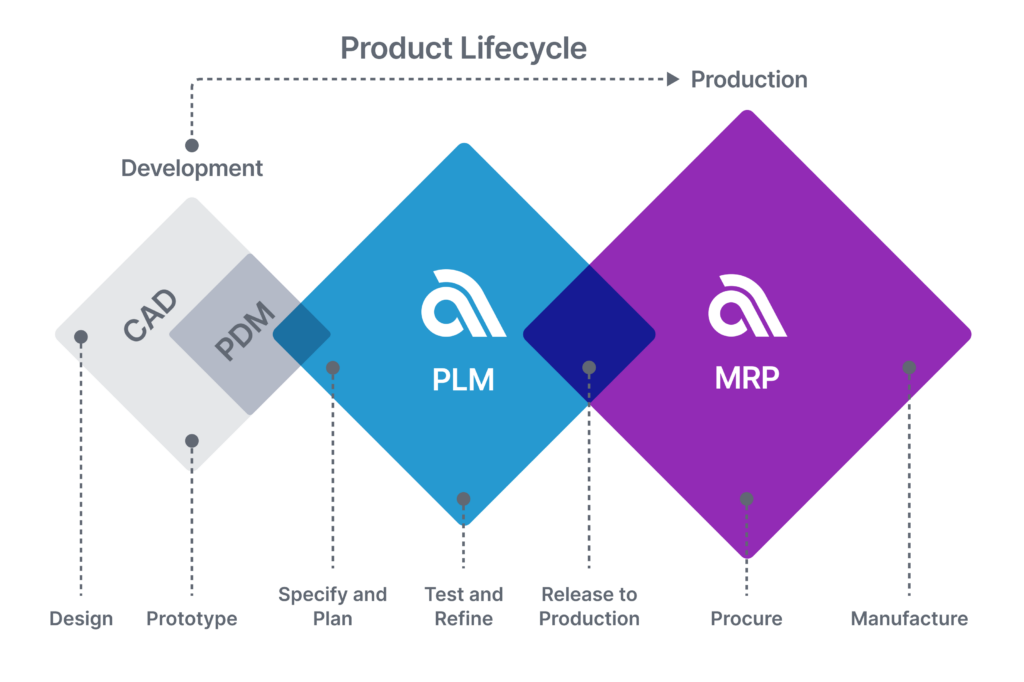

The International Society of Automation has put together a rather extensive article on how modern Product Lifecycle Management (PLM) systems manage Bills of Materials (BOMs) and why that’s been effective for so many manufacturing organizations. It goes into detail about how PLM systems are the best fit for holding the information within and surrounding a product’s BOM, as well as the need for PLM systems to play well with a company’s ERP or MRP system.

The article also touches on how spreadsheet-based management systems fall short of providing the accountability necessary to make sure simple errors are mitigated and handoff processes are streamlined. Read the article to get the more indepth points about the primacy of BOM management in PLM systems.

Of course, if you’re looking to get out of spreadsheets and into a system that can provide all of the benefits laid out in this article, then we also recommend looking at Aligni MRP. The system combines our Aligni PLM system to deliver a highly integrated BOM management solution that checks all the ISA’s boxes.