You might have heard that an Enterprise Resource Planning (ERP) system is the way to go for managing operations, but is it really the best fit for your business?

ERP systems are built for large companies that need to manage complex operations across multiple locations, departments, and vendors. If you’re running a smaller manufacturing business with just one or two facilities, an ERP system might be more than you actually need—adding extra costs and complexity without justifiable benefits. In this article, we’ll explore whether an ERP system is necessary for your business or if another option is more suitable.

What Functionality Does an ERP System Provide?

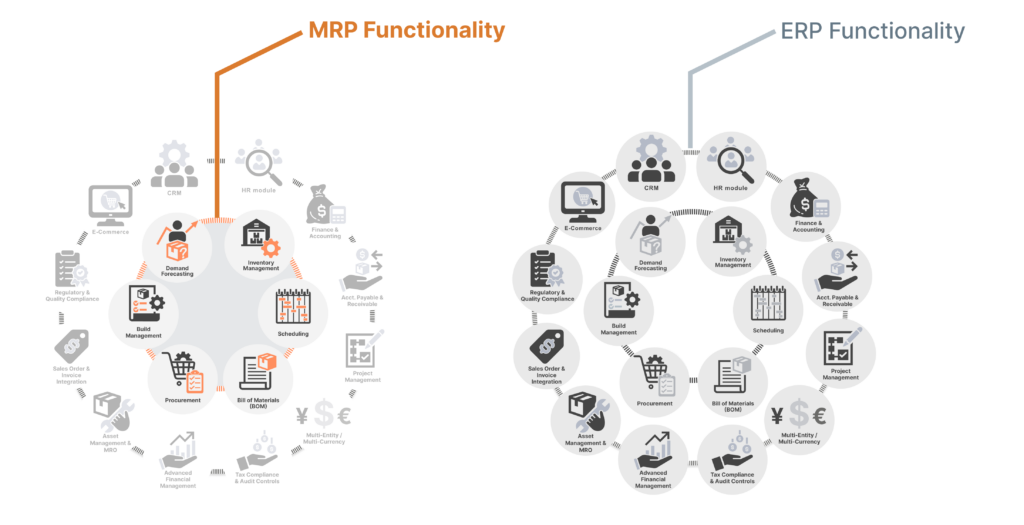

An enterprise resource planning system is an integrated software solution designed to manage and automate organization-wide operations by connecting departments such as finance, human resources, supply chain, sales, and manufacturing within a single platform. ERP provides a holistic approach to business management, ensuring seamless data flow and improved decision-making across all functions. ERP systems are particularly suited for large-scale businesses due to their ability to handle complex workflows, multi-location operations, global supply chains, and regulatory compliance. With advanced business intelligence, real-time reporting, and process automation, ERP systems help large enterprises optimize efficiency, reduce operational costs, and scale effectively in competitive markets.

Are There Alternatives to ERP for SMBs?

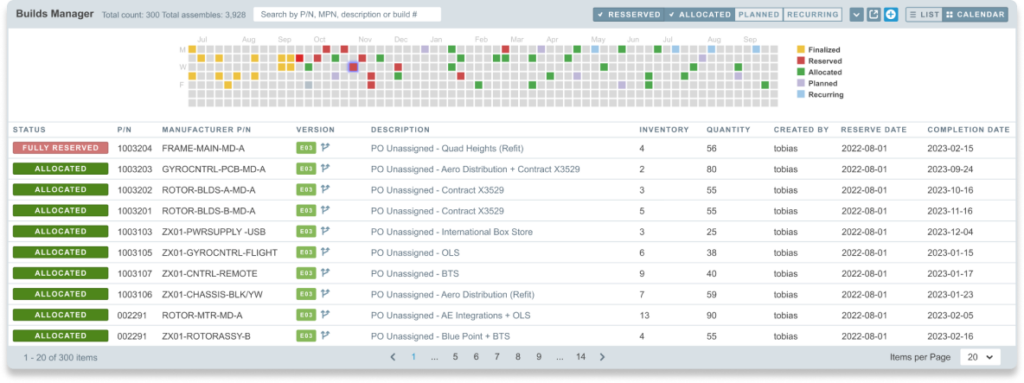

When a product company begins to scale production as they grow, a full-blown ERP isn’t the only path forward. For many Small‑ and Mid‑sized Businesses (SMBs), a dedicated MRP system delivers the mission‑critical capabilities you need right now—inventory visibility, production scheduling, BOM management and vendor coordination—without the cost, complexity and disruption of a broad‑scope ERP rollout. By starting with a best‑in‑class MRP like Aligni, you can standardize your shop‑floor processes, clean up master data and prove ROI in a matter of weeks instead of months. That sharper focus lets your team build confidence in new systems, tighten controls around materials and capacity, and lay a scalable foundation for a phased ERP transition down the road.

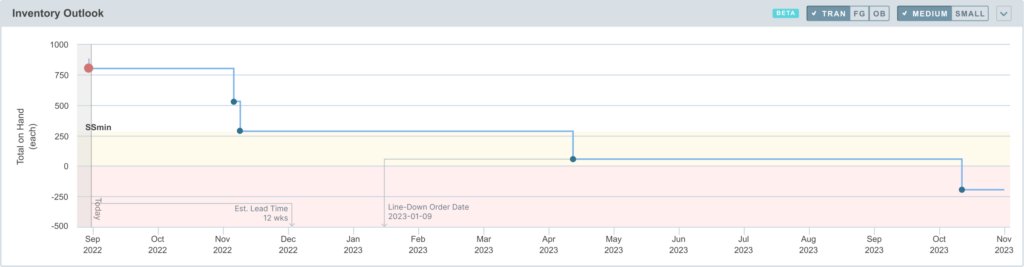

An MRP system ensures manufacturers have the right materials, in the right quantities, at the right time to meet production demands. By analyzing sales orders, production forecasts, and lead times, an MRP system helps businesses optimize material usage, reduce waste, and prevent production delays caused by shortages or overstocking.

Unlike broader enterprise solutions like ERP systems, MRP focuses exclusively on the manufacturing floor and supply chain, making it an essential tool for businesses that need precise control over raw materials and production workflows. The level of detail an MRP system provides ensures that manufacturers can maximize resource utilization without over-complicating their operations with unnecessary enterprise-wide functions.

Since SMBs often have limited budgets and lean production teams, an MRP system provides a cost-effective, streamlined solution that supports growth and scalability while maintaining tight control over inventory and production efficiency.

When Will I Outgrow an MRP System?

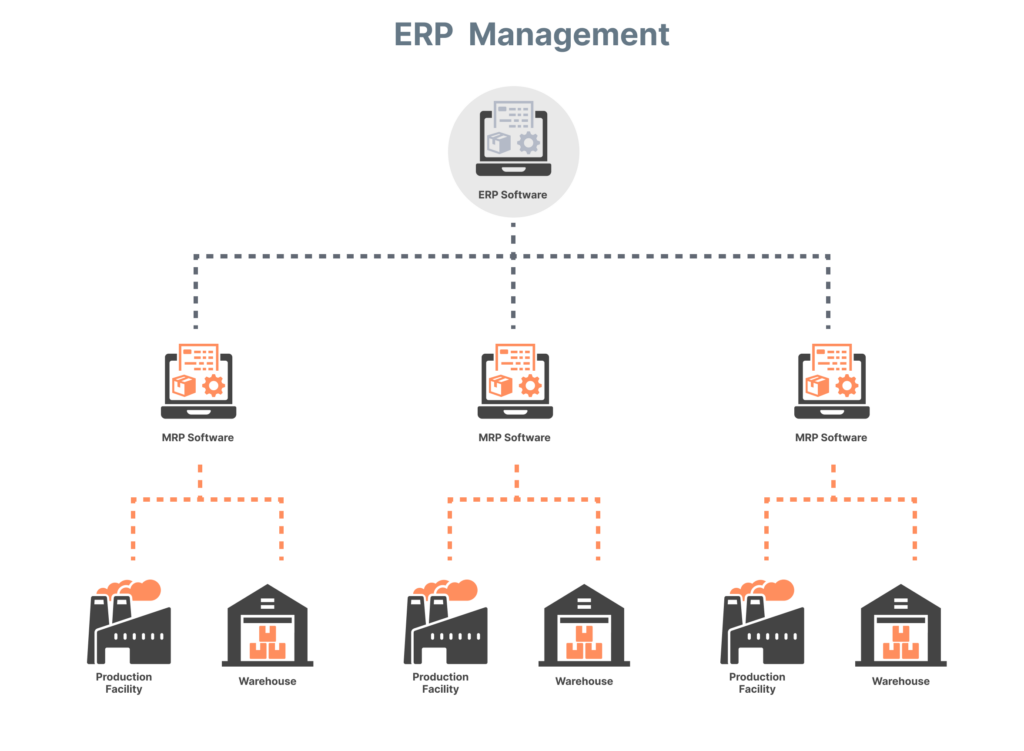

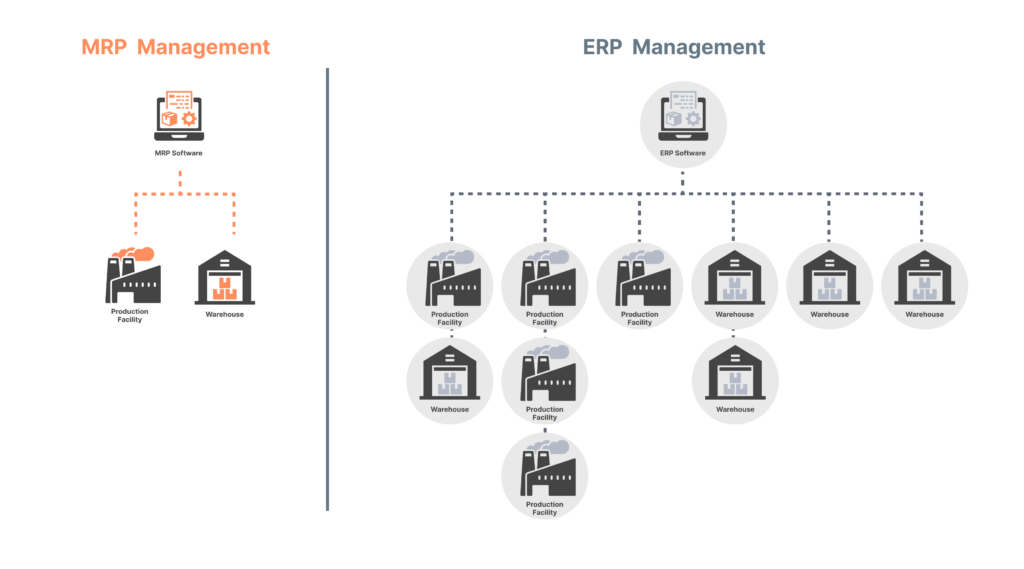

Generally, a company adds ERP functionality on top of existing MRP systems when greater management is needed. Organizations don’t outgrow an MRP system in a single production facility but when the organization has to manage the complexity of several facilities, that’s when the company needs to turn to engaging an overarching system to integrate the operations of the entire company. Then it is time for ERP.

A company may need to add an enterprise resource planning system to its existing material requirements planning system when its business operations grow beyond single facility manufacturing and inventory management. As companies expand, they also face challenges in financial management, human resources, customer relationship management, and multi-location coordination, which an MRP system alone cannot handle.

If a business opens multiple manufacturing sites, works with hundreds of vendors across different regions, or needs to comply with complex tax laws and industry regulations, an ERP system becomes essential for organization-wide integration and data visibility.

Additionally, as companies scale, manual accounting, payroll, and procurement processes can become inefficient, making an ERP system a valuable tool for streamlining workflows and improving decision-making. By integrating an ERP system with an existing MRP, businesses can ensure seamless coordination between production, finance, supply chain, and customer service, enabling them to operate more efficiently and support continued growth.

Does an ERP Provide More Than We Need?

For many small and medium-sized manufacturers, investing in an enterprise resource planning system may be more than what is necessary. ERP systems are designed to manage complex, large-scale operations, integrating multiple business functions such as finance, human resources, supply chain management, and customer relations into a single platform.

ERP systems are most beneficial for companies that operate in multiple locations across large geographic areas, work with hundreds of vendors, or require extensive regulatory compliance, tax reporting, and certifications—factors that typically impact larger enterprises more than smaller manufacturers. However, if your organization operates from only one or two manufacturing locations, an ERP system could introduce unnecessary complexity and costs.

If your current accounting system meets your financial management needs, there may be no need to implement an ERP. Many SMBs can handle payroll, invoicing, and expense tracking with standalone accounting software, avoiding the high costs and complexity of ERP financial modules.

Additionally, if your company does not require extensive inventory tracking or vendor management, an ERP system could be excessive. Businesses with only a handful of suppliers and manageable stock levels typically do not need the advanced supply chain and procurement features that ERP offers.

Taking the Next Steps

If you are a small or medium-sized business thinking it’s time to ditch the spreadsheets or homegrown management system for something purpose built, check out Aligni MRP today. It is free to sign up and ready to take your business to the next level.