Managing costs goes beyond finding the best price. It comes from analyzing true costs, building robust processes, and preparing for the unexpected. These capabilities are built on managing inventory and purchasing data and sharing it effectively. The faster that data is shared across the company the faster it can be turned into reliable information for everyone in the organization to use in making better decisions.

Maintain and Share Up-to-Date Pricing Information

Accurate assembly pricing starts with using current component pricing information. That means ensuring the data is conveyed from the people who interact with the vendors to the people who build the bills of materials in a timely fashion. Ideally, there needs to be a direct conduit from the purchasing department to the engineering group to provide the most current pricing information. At the same time, this conduit needs to be easily accessible, trusted, and utilized to prevent data from being siloed by either group. Otherwise, decisions will be made on older or obsolete data that could cause issues for the organization in several ways.

Completely Understand All Demands on Inventory

While pricing is paramount, other components of the true part cost cannot be ignored, especially those associated with shipping. In normal circumstances, these costs may be absorbed into the provided part cost or they may be counted in another fashion. When these parts are found to be out of stock, a new, larger shipping cost is dealt with: the rush price. This increase may stem, for example, from moving from truck to air shipping. It may also include a charge for expediting the order through the fulfillment process at the vendor. Regardless of how the extra cost is affixed, its real origin is a lack of visibility into stock on hand and how long it takes to get more in inventory.

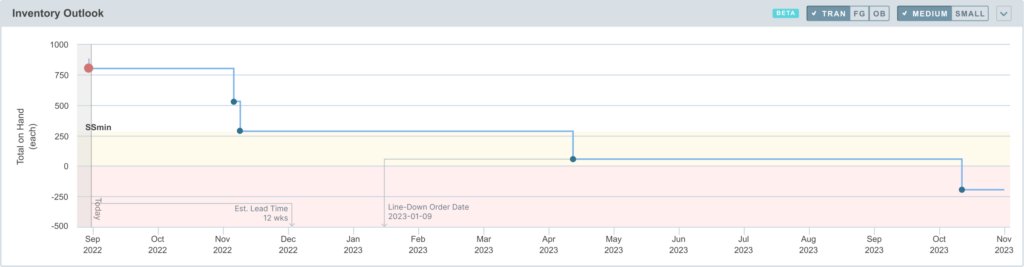

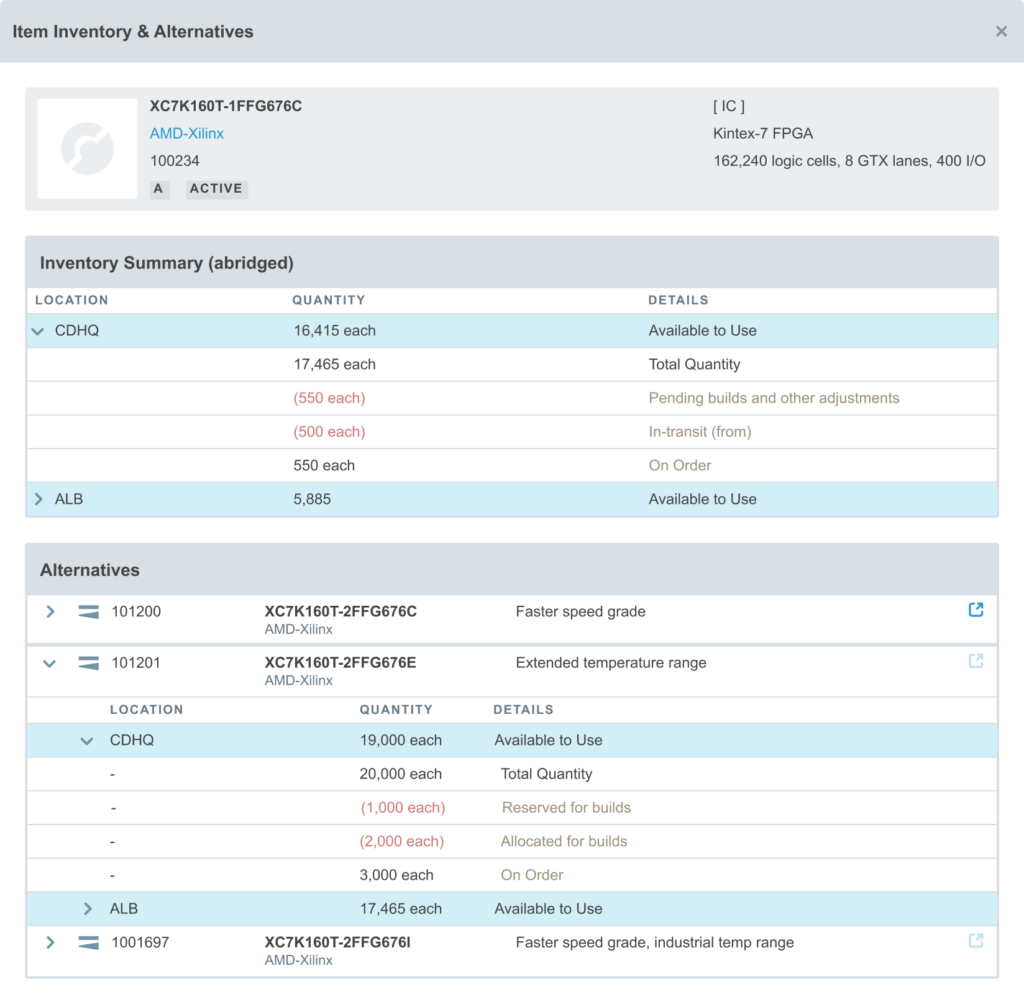

To thwart this situation, organizations need to have a greater understanding of the parts and materials they have on hand and how those are being consumed over time. This becomes even more important when there are several builds that utilize the same components. The buyer/planner needs to account for all production demands of the part to effectively determine what quantities they need to have on hand at any given time. Accurate inventory forecasting becomes more and more difficult with every new production build added to the schedule as each new job invites errors as much as omissions from the growing complexity.

Organizations also need to have an understanding of how long it takes to restock materials after consumption before extra costs are incurred to replenish inventory levels. Without this knowledge, part costs can increase drastically from expediting charges and more expensive shipping incurred to meet the next production deadline. These additional charges can quickly accrue. If margins are narrow, recurring rush charges can quickly diminish profitability, especially if these added shipping charges are not being provided the attention they require.

Preemptively Monitor Price Changes

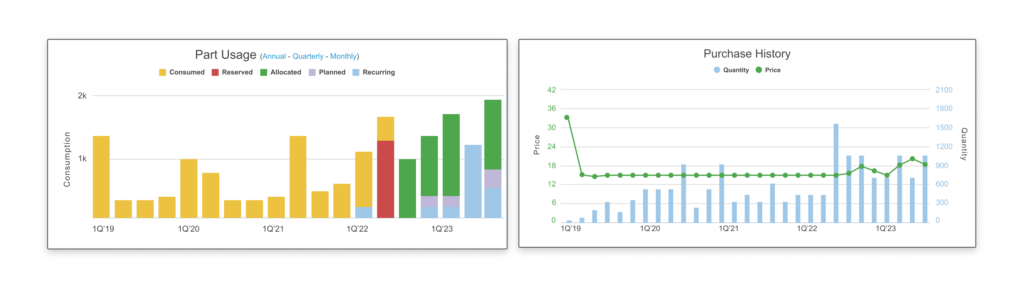

Pricing comes in varying degrees of stability. Some parts hold price seemingly indefinitely while others can vary erratically. The rest fall somewhere in between. One thing that can be certain is that change will happen. It is best to be vigilant.

The surest way to manage potential price fluctuations is to ensure pricing is revisited often and based on the aforementioned frequently updated quoting practices. The next level is to watch price behavior over time. When pricing decisions are made on an ad-hoc basis, some trends may be uncovered, while other intricacies might be overlooked. If prices are moving directionally, then buyers will be ready to make more strategic decisions. Further, tracking the performance of purchasing volumes on prices can help illuminate whether buying strategies should be changed to be more efficient.

Preparing for the Unexpected

Not every operation goes as planned. A good manager prepares for the potentiality of unforeseen events including trusted vendors running out of stock themselves or unexpected changes in pricing.

Backup Vendors for Unforeseen Events

One method of insuring against such events is to maintain a list of other vendors who could provide materials when approved vendors are unable to or cannot maintain pricing. This should be done before issues arise. Ideally, the organization should build a vendor list and maintain it in the same fashion as their approved vendors. This maintenance would include keeping contact with the suppliers and tracking pricing on components. More prepared buyers and purchasing managers would ensure that these vendors are not only set up in their systems but their organization has performed all of the activities necessary to buy from the supplier when the need arises.

Retain a Database of Alternate Parts

Over the course of a production run or over the lifecycle of a product, changes to the availability of components can happen. Parts could be sunset by manufacturers, production of the part can become sporadic, causing variance in availability, or demand can increase from larger manufacturers, causing unforeseen droughts in supplier stocks.

With these potentialities, buyers should also maintain a database of alternate parts that can be substituted for specified components. Again, these parts should be selected before issues arise with the specified parts. This database of alternates should be connected to the specified parts, so as to reduce the elapsed time in changing over. It is recommended to ensure the alternate part pricing data be maintained with a level of recency similar to the specified parts they aim to replace.

Managing the Process with the Right Tools

Of course, all this preparedness is highly data dependent. It also requires a high level of interconnectivity between departments to get the most benefit. Certainly all of this could be done with spreadsheets – and for small organizations that could be enough. As a company grows, maintaining all this data and ensuring its utility requires the use of specialized software.

Aligni MRP is designed to not only manage the vast amount of data a well-designed product cost management process requires but it is also built to help users across the organization get greater value out of it.

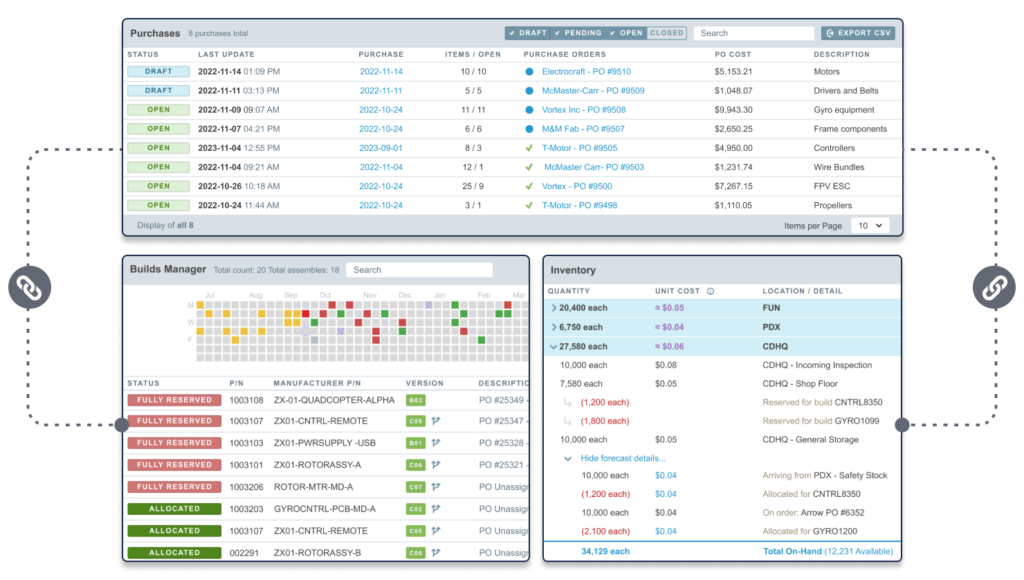

While Aligni is the repository for both product information and purchasing data, its ability to be the conduit between purchasing and engineering is where it provides the greatest value. When an organization migrates to using the MRP system, it is migrating to a system that centralizes all of the company’s data and makes it immediately accessible to all in the organization. This means engineers are able to utilize the most current pricing available from the purchasing department. Aligni also provides the parts and materials required for upcoming orders to the purchasing group. This sharing extends to when updates happen to the underlying pricing and availability of materials. When part prices change or demand increases, all departments are made aware when the adjustments happen.

Aligni’s collaborative benefits extend beyond data accessibility, it reduces the time needed for the organization to react to these changes. Organizations won’t have to wait for meetings, emails, or phone calls to learn about changes. BOMs, builds, and part demand requirements are updated across Aligni when new information is provided. Updates happen seamlessly and without the double checking and process that spreadsheets would require.

When alternate parts are managed in the same system as the specified components, accessing and managing both is a highly connected operation that increases a company’s agility in the face of change. In the unlikely event that specified parts are not available in stock or via an approved vendor, Aligni makes it easy to locate suitable replacements from other vendors saved into the system. The MRP also provides quick access to alternate parts the company has researched in the event the specified parts become unavailable.

Managing everything within one system provides users the benefits from understanding inventory demand across all production operations. As a Material Requirements Planning system, Aligni is built to manage all the production builds the company is working on or plans to build. It is able to present the combined demands of all jobs and display how much of each component is needed and when. Further, Aligni displays the pre-set reorder timelines for each part, should stock indicate replenishment is necessary. This means buyers can purchase more efficiently by combining all production needs rather than reacting to each build, lowering costs and getting better terms.

Taking the Next Step in Maintaining Cost Accuracy

Putting everything mentioned in perspective, the best way to hold pricing accuracy and reduce cost surprises comes from adequately managing the underlying data that goes into the processes. That requires not only the most up to date information but the tools to manage that data effectively – Aligni MRP. Sign up today!