Past performance is key to getting the future right. Purchasing history is a buyer’s best resource.

Purchasing is a process that finds its efficiency in knowing as much about what’s going on as possible. That means data. To get the best prices, the best delivery times, and to make sure production doesn’t stall, a buyer needs to be as well-informed about what they are buying as they can be. Merely living in the present with today’s quotes is less than half what’s needed.

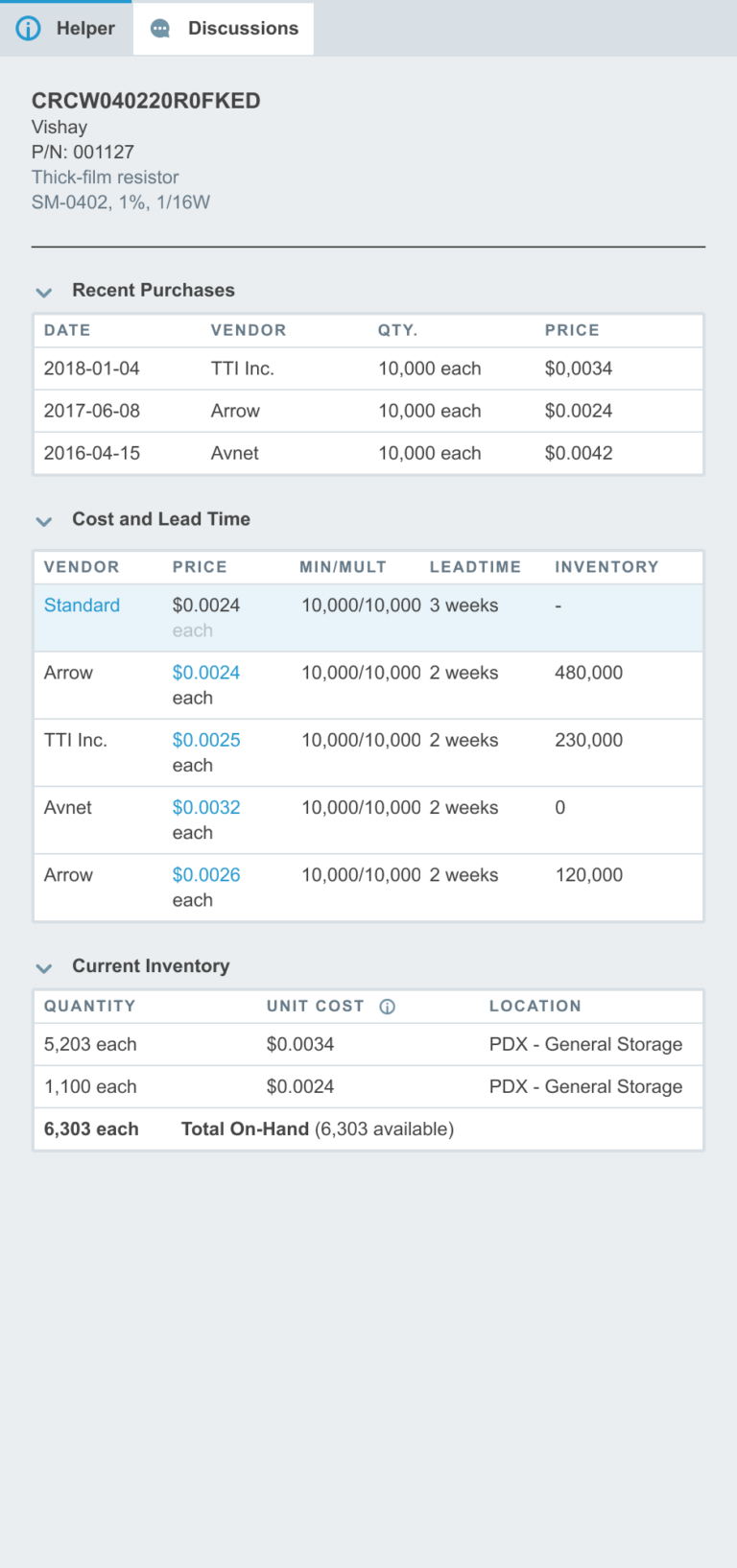

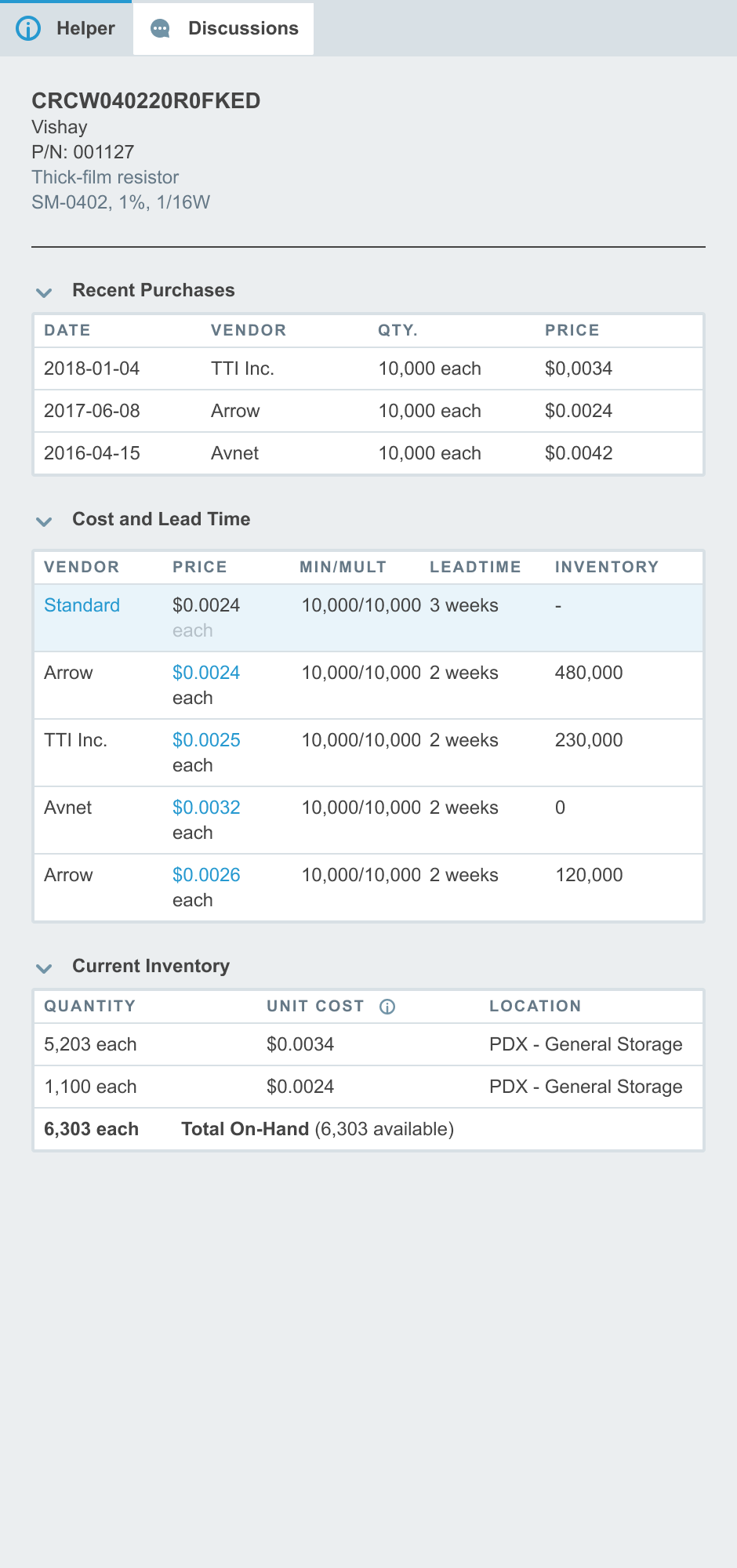

The well-informed buyer also needs to have at their disposal the historical transactions and supplier performance to make the best decisions on how, when and from whom to buy. Most firms store historical purchasing transactions in some manner. Having that information easily available and searchable is what’s really needed to get the most out of it.

Getting to your data

All this purchasing data has also to be in a format that allows it to be compared over time and against current quotes. Spreadsheets just can’t cut it. There is simply too much data that needs to be stored and analyzed that tabular formats are incapable of handling it. That means a purpose-built software is needed.

Typically, small- and medium-sized manufacturers turn to material requirements planning (MRP) software to manage the information. Built on an item master database, these systems are designed to make it easy to store and put this information to use.

The benefits of utilizing your purchasing data

While many buyers and supply chain managers can quickly conjure scenarios where having a little more insight from past data could make a difference, we’ve put together a more comprehensive overview of what can be had when a firm makes the commitment to utilize its purchasing data, below.

Data-Driven Decision-Making

Buyers use historical purchasing data to make informed, data-driven decisions.

By analyzing past purchases, they can identify trends, patterns, and insights that inform procurement strategies, supplier selection, pricing negotiations, and inventory management. Data-driven decisions lead to more efficient and cost-effective purchasing practices.

Performance Evaluation and Improvement

Storing purchasing data allows buyers to evaluate supplier performance over time.

They can assess factors such as on-time delivery rates, product quality, pricing consistency, and compliance with contract terms. This evaluation helps improve supplier management, including supplier selection, performance improvement efforts, and contract renegotiations.

By having a historical record of performance, buyers can hold suppliers accountable and work collaboratively to address issues and achieve better outcomes.

Greater Efficiency and Process Optimization

Purchasing data stored in an MRP system streamlines procurement processes and enhances efficiency. Buyers can automate routine tasks, such as generating purchase orders and calculating reorder points, based on historical data and predefined rules. This reduces manual effort and minimizes the risk of errors. Additionally, the data helps optimize inventory levels, supplier relationships, and overall procurement operations, resulting in cost savings and improved supply chain performance.

While there are many more benefits, storing purchasing data in an MRP system empowers buyers with valuable information for informed decision-making, supplier performance evaluation, and process optimization. These benefits ultimately contribute to more efficient and effective procurement practices, better supplier relationships, and cost control.

Ready to start being more data-driven in purchasing operations? Then it’s time to make the first step and adopt an MRP system like Aligni. Learn more about our MRP offerings or try our online demo!