MRP

The Benefits of Using Aligni MRP to Manage Safety Stock Levels.

Material Resource Planning or Material Requirements Planning (MRP) is used to help plan and control inventory and resources for manufacturing processes

Safety stock refers to the extra inventory held beyond the expected manufacturing demand to mitigate the risk of stockouts. This material acts as a buffer to account for variability in demand, supply chain disruptions, and lead time uncertainties. Manufacturers maintain safety stock to ensure they can meet customer demands, prevent production disruptions, and manage unforeseen fluctuations in demand or supply.

While some manufacturers still rely on spreadsheets to manage this inventory, many companies have found using Material Requirements Planning (MRP) systems like Aligni MRP to manage safety stock to be much more efficient. This can be easily noticed in the benefits these companies enjoy from using purpose-built MRP software. We’ve broken out several of the biggest advantages that can be had from retiring spreadsheet-based safety stock management processes.

Optimizing Inventory Levels

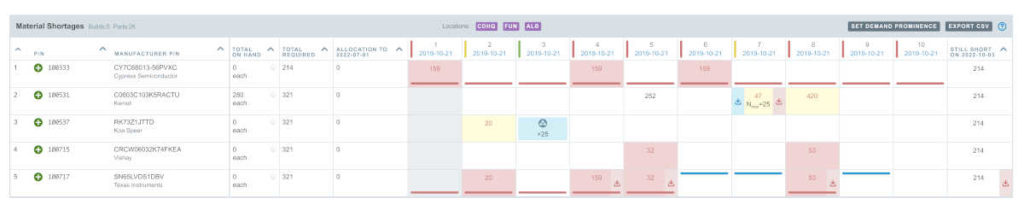

Aligni MRP helps manufacturers maintain optimal safety stock levels by making it easier to identify factors such as demand variability, lead time variability, and service level targets. MRP systems utilize the historical data manufacturers have on hand to calculate the appropriate quantity of safety stock needed. That stock helps mitigate the risk of stockouts and costly expedited ordering. On the other hand, it works to ensure inventory levels are optimized, reducing excess stock and associated carrying costs.

Improving Customer Service

With the right amount of safety stock in place, manufacturers can better meet customer demand. Safety stock managed through Aligni MRP acts as a buffer, enabling timely order fulfillment even in the face of unexpected demand fluctuations or supply disruptions. This leads to improved customer satisfaction, as orders can be fulfilled promptly without delays or backorders.

Explore what Aligni can do for your organization

Enhancing Supply Chain Resilience

Aligni MRP contributes to the resilience of the company’s supply chain through effective safety stock management. By accounting for demand and lead time uncertainties, Aligni helps manufacturers anticipate and mitigate potential disruptions. Safety stock provides a cushion against unexpected fluctuations, enabling the supply chain to continue operating smoothly even in challenging circumstances.

Minimizing Stockouts and Production Delays

With accurate safety stock management through Aligni MRP, manufacturers can minimize stockouts and production delays. By having adequate safety stock levels, the risk of stockouts due to unexpected demand spikes, supplier delays, or production issues is significantly reduced. This helps maintain uninterrupted production schedules and on-time delivery to customers.

Planning Inventory Efficiently

Aligni MRP integrates safety stock calculations into inventory planning processes. This integration ensures that safety stock levels are dynamically adjusted based on changing demand patterns, lead time variations, and service level requirements. It enables manufacturers to make data-driven inventory planning decisions, optimizing the balance between inventory investment and the risk of stockouts.

Saving Inventory Costs

Effective safety stock management using MRP systems like Aligni leads to cost savings for manufacturers. By maintaining optimal inventory levels, the need for excess inventory is minimized. This reduces holding costs such as storage, insurance, and obsolescence. Additionally, mitigating stockouts through proper safety stock levels helps avoid costly production delays and higher-cost rush orders to fill those inventory gaps.

Making Data-Driven Decisions

Aligni MRP provides manufacturers with real-time visibility into inventory levels, demand forecasts, lead times, and safety stock calculations. This comprehensive data empowers informed decision making related to safety stock management. Supply chain managers can analyze performance metrics, conduct scenario analysis, and implement improvements based on accurate and up-to-date information.

Streamlining the Procurement Process

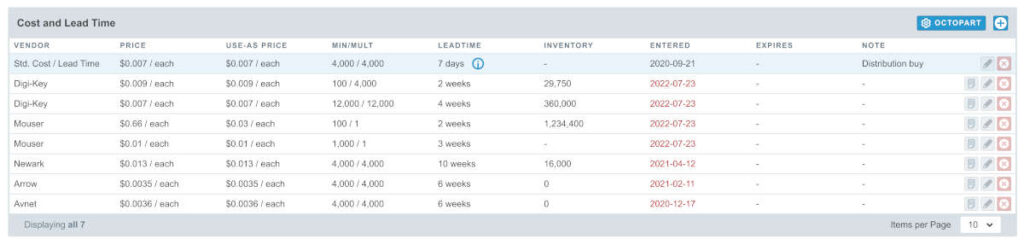

Aligni assists in procurement processes by going well beyond simply incorporating safety stock requirements. The system also provides ActiveQuote functionality. This capability integrates the purchasing process further into MRP activities and creates value from the information developed in the procurement process. Aligni ActiveQuote is a vendor portal that allows buyers and vendors to manage RFQs, quotes, and orders electronically. By providing a direct connection to inventory planning and the buying process, firms can become more responsive to changes, reduce errors and stay informed on changes in part pricing and availability trends over time.

Bringing it all together

By leveraging Aligni MRP for safety stock management, manufacturing firms can achieve optimal inventory levels, improve customer service, enhance supply chain resilience, minimize stockouts, streamline procurement, and realize cost savings. These benefits contribute to efficient operations, improved customer satisfaction, and a competitive advantage in the market.

If you’re looking for a solution beyond juggling spreadsheets to manage your inventory operations, it’s time to sign up online for Aligni MRP today!

Start your 30-day free trial

Join over 4,000 teams that are manging their manufacturing with Aligni.