As a component of a broader Engineering Change Management system, Engineering Change Requests (ECRs) are used in manufacturing to identify and discuss improvements, enhancements, updates, and fixes to a product design. An ECR is a formal document that outlines modifications or changes to engineering drawings, components, products, processes, or services. Previously, this has been done in the past as a paper-based process. Increasingly manufacturers are turning to software like Aligni to manage the process more effectively.

The engineering change request process may be used to identify and address quality issues in manufacturing. It also provides a way for manufacturers to update components used in their products. ECRs help manufacturers keep up with changing customer needs, new technologies, and safety regulations. Engineering Change Requests do this by ensuring that engineering drawings, components, and processes are kept up-to-date. Ultimately, ECRs provide a streamlined system of communication between engineering departments and other stakeholders involved in the production process.

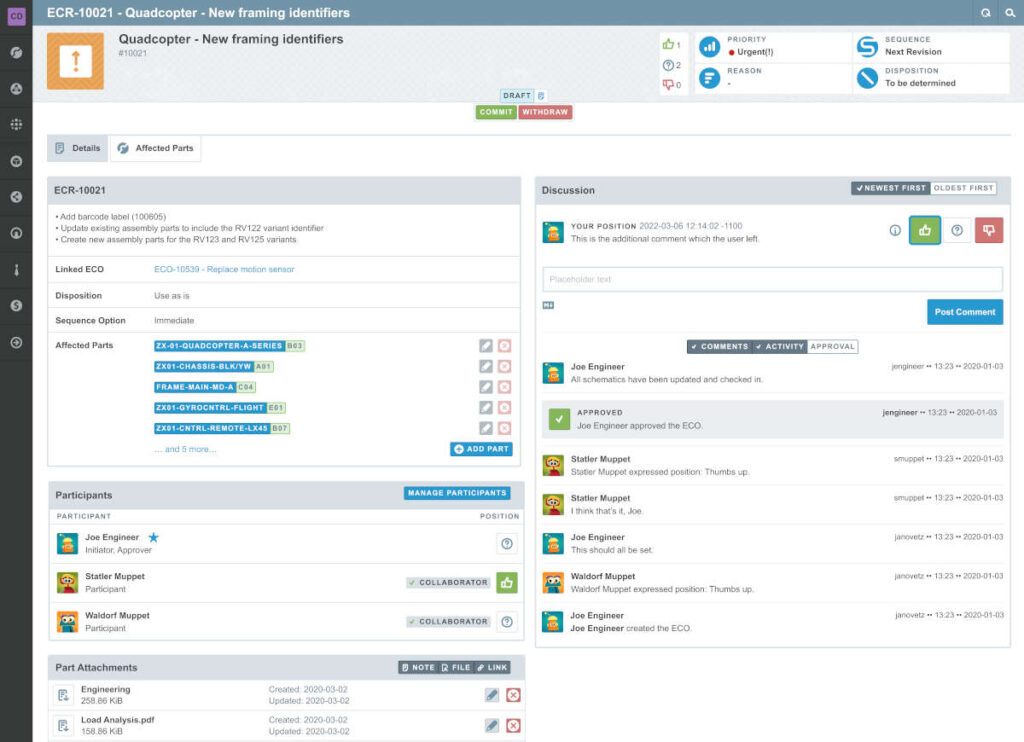

ECRs in Use

The engineering change request process involves several steps: defining the problem, proposing a solution, implementing the change, validating compliance with requirements, and documenting the change. This process can engage a number of personnel and departments. This is another reason software ECR management solutions are preferred. Specifically, the software system can act as a single source of truth in the process. It can actively manage the routing of changes and notifications, rather than chasing forms around a facility.

When an Engineering Change Request is initiated by a manufacturer, they must first define the problem using detailed information such as product design documents, engineering drawings, and specifications of related components typically found in the bill of materials. Once the issue is identified, the staff then evaluate potential solutions. It’s determined which one is most suitable from these solutions. The changes may include selecting new materials or improving existing designs. Finally, manufacturers must ensure that the engineering changes meet regulatory requirements and quality standards.

The changes must also be conveyed to the affected departments. The notifications make sure the changes become a reality. In most cases, this communication is done through Engineering Change Orders (ECOs). Through ECOs, the changes are connected to the products or assemblies they affect. Once again, by using software like Aligni to manage the entire process, the right documentation is updated automatically and instantly available to the right people.

Bringing It All Together

By implementing an effective engineering change request process, manufacturers can reduce costs associated with product development while maintaining a high level of quality assurance. This is crucial for maintaining customer satisfaction as well as protecting a company’s reputation in the marketplace.

If you’re looking to get in front of your quality and inventory issues, it’s time to consider moving to a software-based ECR system. Sign up for a free trial of Aligni.

Start your 30-day free trial

Helping You Make Great Things…Better.