Capacity planning and Material Resource Planning (MRP) are two essential processes that work together to optimize production in manufacturing. Capacity planning is the process of determining the production resources required to meet the demand for a product or service. The estimation process involves analyzing current sales, historical sales data, forecasting future demand, and determining the production resources needed to produce the required output. These resources planned for may include machinery, labor, raw materials, contract manufacturers, and other inputs.

Material resource planning, on the other hand, is typically a software-based inventory control and production planning system, like Aligni MRP. These systems help manufacturers determine the parts and materials they need to produce a product, schedule production runs, and track inventory levels. MRP takes into account the lead times for raw materials and the time required to produce finished products.

Processes Working Together

Capacity planning and MRP work hand-in-hand by ensuring manufacturers have the resources they need to produce the required output to meet customer needs. Capacity planning helps determine the resources needed, while MRP helps ensure that those resources are available when needed. Connecting manufacturing capabilities with inventory availability is where these two processes meet. Integrating the processes is where companies see the most benefit. For small to medium sized businesses, this can be achieved through a properly utilized MRP system.

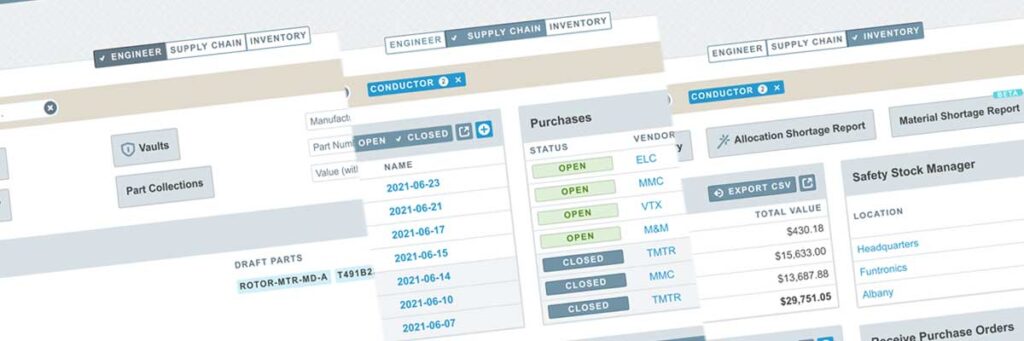

Most materials requirements planning systems offer the basic functions needed by manufacturers. Some MRP systems have advanced features that start to automate the inventory management process to ensure the manufacturer has the capacity it needs. For example, if the capacity planning process determines more raw materials are needed to produce a product, systems like Aligni MRP provides tools to quickly quote and order the items that are short. These abilities ensure those materials are available when needed.

Aligni MRP is designed to make it much easier for manufacturers to estimate demand from sales projections and orders. With its built in Demand Estimator and safety stock tracking capabilities, Aligni can graphically describe inventory needs in the future. This makes it easy for the inventory buyer/planner to better connect stock needs to production capacity and sales needs.

Additionally, integrating capacity planning and MRP helps manufacturers optimize their production processes. Capacity planning ensures that the production capacity is aligned with demand, while MRP helps minimize excess inventory and production costs.

MRP systems like Aligni are designed to be accessed not only by inventory personnel but also production managers. It does this through user interfaces designed for each department’s needs. This means every department is working off the same data. When changes occur, the entire organization is kept up to date.

By working together, these processes help manufacturers balance their production capabilities with market demand, optimize their use of resources, and maximize profitability. This integration reduces overproduction of unneeded products, as well as making sure there’s enough resources to properly hit sales requirements.

Learn More

These are just a few of the ways MRP systems can help the capacity planning process. If these areas are something your firm should employ, it’s time to check out Aligni MRP and learn the other ways Aligni can help make your facility more efficient.

Start your 30-day free trial

Helping You Make Great Things…Better.